Job 11

Standard test method for ductility of bituminous materials

ASTM DESIGNATION: D 113-07

SCOPE & SIGNIFICANCE:

- This test method describes the procedure for determining the ductility of a bituminous material measured by the distance to which it will elongate before breaking when two ends of a briquet specimen of the material, are pulled apart at a specified speed and at a specified temperature. Unless otherwise specified, the test shall be made at a temperature of 25 (±)5°C and with a speed of 5 cm/min (±) 5.0 %. At other temperatures the speed should be specified.

- This test method provides one measure of tensile properties of bituminous materials and may be used to measure ductility for specification requirements.

- Bituminous materials used in pavement construction should possess sufficient ductility otherwise the pavement would crack due to temperature or traffic stresses and may render the pavement pervious and damage the pavement structure.

- The ductility value varies from 5 to over 100 cms.

- Several agencies have specified minimum ductility values for various types of bitumen pavements. However, a ductility of 100 cms is specified generally for bituminous construction.

- Roads expand at daytime while they contract at night. So, if the bitumen is not adequately ductile, cracking will occur.

- Range of specific gravity of bitumen is 0.97 – 1.02.

- More than one grade may be used in the same project. For example; we may use grade 80/100 on the main traffic lane and lower grades on the arteries.

RELATED THEORY:

DUCTILITY:

“The ductility of a bituminous material is defined as the distance in centimeters, to which it will elongate before breaking when two ends of a briquet specimen of the material, are pulled apart at a specified speed and a specified temperature”.

Unless otherwise specified, the test shall be made at a temperature of 25 ± 0.5 °C and with a speed of 5 cm/min ± 5.0 %. At other temperatures the speed should be specified.

IMPORTANCE OF DUCTILITY:

The ductility of a bitumen specimen tells us about

- Tensile strength of bitumen

- Grade of sample (ductility grade)

DEPENDENCE OF ASPHALT DUCTILITY:

Ductility of asphalt depends upon the

- Grade of asphalt

- Pouring Temperature

- Dimensions of briquet

- Levelling of the mould

- Test Temperature

- Rate of Pull

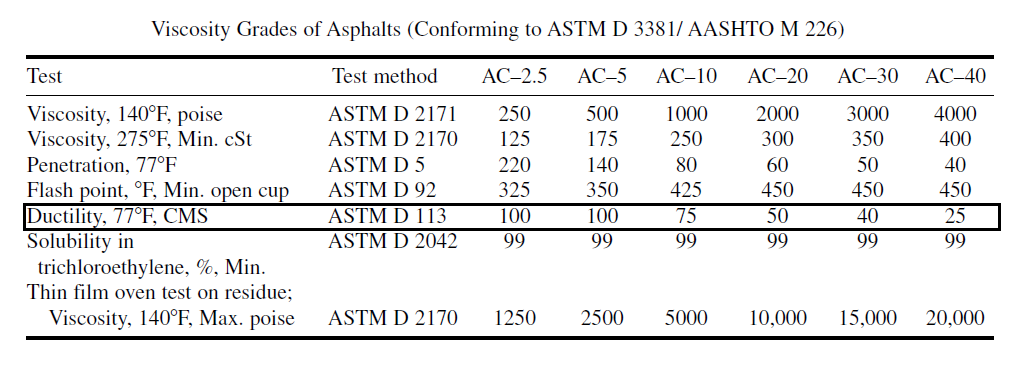

VISCOSITY GRADES OF BITUMEN:

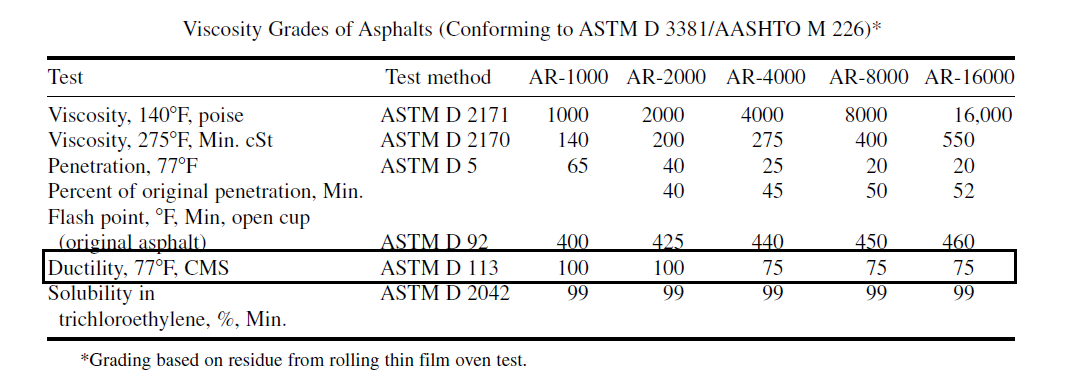

VISCOSITY GRADES OF BITUMEN:

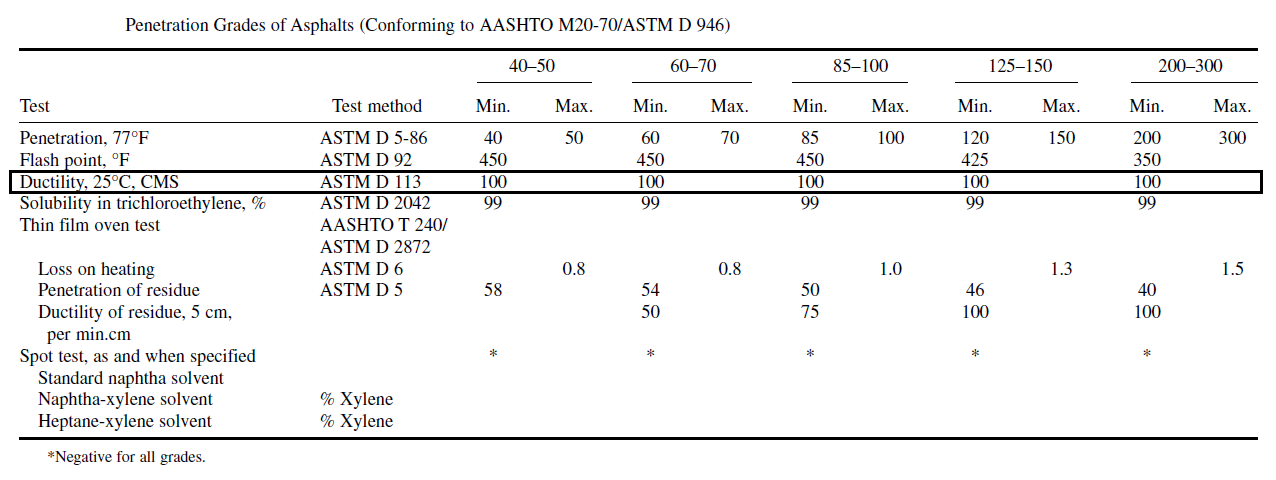

PENETRATION GRADES OF BITUMEN:

Source: Petroleum fuels manufacturing handbook by Surendar Prakash PHD

Note:

If we know the ductility of bitumen from this test then the grade of bitumen can easily be known from the above tables.

APPARATUS:

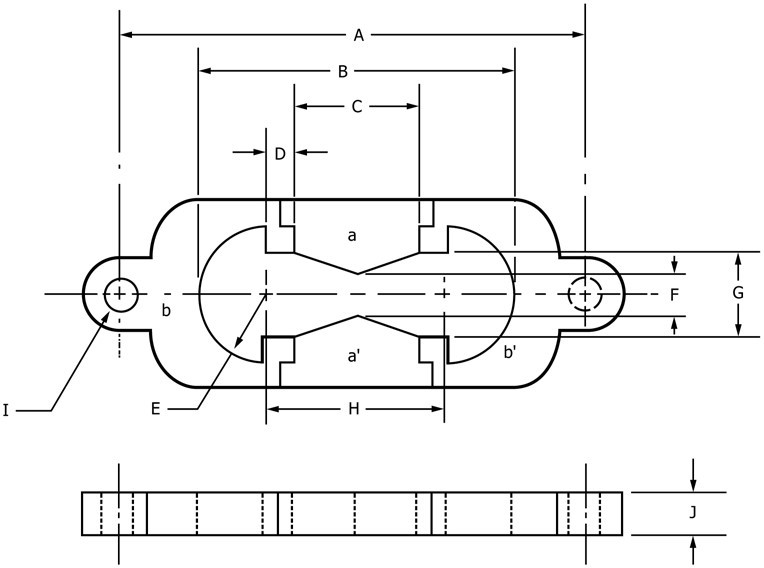

- Mold—The mold shall be similar in design to that shown in 1. The mold shall be made of brass, 10.0 (±) 0.1 mm thick, the ends b and b‘ being known as clips, and the parts a and a‘ as sides of the mold, with a brass base plate that is larger than the assembled mold. The dimensions of the assembled mold shall be as shown in Fig. 1 with the permissible variations indicated.

- Water Bath for Conditioning Specimens—A water bath capable of maintaining the specified test temperature, varying not more than 0.5°C from this temperature. The specimen shall be immersed and supported such that it is surrounded by water.

- Testing Machine—For pulling the briquet of bituminous material apart, any apparatus may be used which is so constructed that the specimen will be continuously immersed in water, while the two clips are pulled apart at a uniform speed, as specified, without undue vibration. A variation of 65 % is permissible. The water in the tank of the testing machine shall cover the specimen both above and below it by at least 2.5 cm and shall be maintained within 60.5°C of the test temperature. The testing machine shall incorporate a means by which the elongation at the time of rupture can be measured in centimeters.

- Thermometer—A thermometer having a range shown as follows:

| Temperature Range | ASTM Thermometer |

| −8 to 32°C | 63C |

| 18 to 89°F | 63F |

- Release Agent—A mixture such as glycerin and Dextrin, talc or Kaolin (china clay) or Versamid Resin and mineral oil used to coat the bottom and sides of mold to prevent the specimen from sticking to the mold. Other materials may be used for this purpose if they have been shown not to affect the physical properties of the test specimen

- Oven—An oven capable of maintaining within 65°C (610°F) of the temperature required to heat the sample so it is just fluid enough to pour.

- Trimming Tool—A straight-edged putty knife or spatula wider than the specimen for trimming.

- Specific Gravity Additive—A substance such as methyl alcohol, sodium chloride or ethylene glycol used to adjust the specific gravity of the water bath to prevent specimen from coming to the surface of the water or touching the bottom of the bath. Other additives may be used if they have been shown not to affect the physical properties of the specimen.

- Sieves—A 300-µm (No. 50) sieve.

Figure 1: Mold for ductility test specimen

Figure 1: Mold for ductility test specimen

A—Distance between centers, 111.5 to 113.5 mm.

B—Total length of briquet, 74.5 to 75.5 mm.

C—Distance between clips, 29.7 to 30.3 mm.

D—Shoulder, 6.8 to 7.2 mm.

E—Radius, 15.75 to 16.25 mm.

F—Width at minimum cross section, 9.9 to 10.1 mm.

G—Width at mouth of clip, 19.8 to 20.2 mm.

H—Distance between centers of radii, 42.9 to 43.1 mm.

I—Hole diameter, 6.5 to 6.7 mm.

J—Thickness, 9.9 to 10.1 mm.

PROCEDURE:

- Assemble the mold on a brass plate. Coat the surface of the plate and interior surfaces of the sides a and a‘, 1, of the mold with a thin layer of a mixture of release agent. The plate upon which the mold is placed shall be flat and level so that the bottom surface of the mold will be in contact throughout. Carefully heat the sample to prevent local overheating until it has become sufficiently fluid to pour. After a thorough stirring, pour it into the mold. In filling the mold, take care not to disarrange the pieces of the mold, thus distorting the specimen shape. Pour the material in a thin stream back and forth from end to end of the mold until the mold is more than level full. Allow the filled mold to cool to room temperature for 35 (±) 5 min. Then place it in the water bath at test temperature for 35 (±) 5 min. Remove the test specimens from the water bath and immediately trim the excess material with the trimming tool to make the molds just level full.

- Keeping Specimen at Standard Temperature—Place the trimmed specimen and mold in the water bath at the specified temperature for 90 (±) 5 min. Remove the specimen from the plate by a shearing action between specimen and plate, avoiding any bending of the specimen. Remove the side pieces a and a‘ being careful not to distort or fracture the specimen.

- Testing—Attach the rings at each end of the clips to the pins or hooks in the testing machine and pull the two clips apart at a uniform speed as specified until the specimen ruptures or reaches the length limitations of the testing machine. Measure the distance in centimetres through which the clips have been pulled to produce rupture or final length.

REPORT

- A normal test is one in which the material ruptures near the center of the specimen or reaches the length limitations of the testing machine. A rupture occurring at either clip shall not be considered normal.

- If the bituminous material comes in contact with the surface of the water or the bottom of the bath, the test shall not be considered normal. Adjust the specific gravity of the bath by using a specific gravity additive as described so that the test specimen neither comes to the surface of the water, nor touches the bottom of the bath at any time during the test.

- Report a normal test as the ductility of the sample. If a normal test is not obtainable, report the ductility as being unobtainable under the conditions of the test. If rupture does not occur due to length limitations of the testing machine, report ductility as the length limitation in cm+ (for example, 150 cm+). If this testing is performed on less than three replicates of the same sample due to insufficient material, include the number of replicates used in the test report.

- In the event of a discrepancy, the referee method shall be to perform the test using three replicates. If the discrepancy involves a distillation residue, pour the material through a 300-µm (No. 50) sieve that has been preheated at 135(±)5°C (275 (±) 10°F) prior to pouring into test molds. Report the average of three normal tests as the ductility of the sample.

OBSERVATIONS & RESULTS

| Sr. # | DESCRIPTION | RESULT |

| 1 | Grade of Bitumen | 80/100 |

| 2 | Pouring Temperature | 140 °C |

| 3 | Test Temperature | 25 °C |

| 4 | Period of Cooling | |

| a)- in Air | 30 min | |

| b)- in water bath – before trimming | 60 min | |

| c)- in water bath – after trimming | 0 min | |

RESULTS & COMMENTS:

Length of bitumen= 92.5 cm

According to this result, the viscosity grade of bitumen is AC-10

And for AC-10 penetration grade is 80/100