Job # 3:

Determination of Relative Density (Specific Gravity) And Water Absorption of Different Aggregate

Code description:

(ASTM C-127-88)

Scope & Significance:

This test method covers the determination of specific gravity and absorption of coarse aggregate. The specific gravity may be expressed as bulk specific gravity (OD), bulk specific gravity (SSD) (saturated-surface-dry), or apparent specific gravity. The bulk specific gravity (SSD) and absorption are based on aggregate after 24 h soaking in water.

This test method is not intended to be used with lightweight aggregates. The pores in lightweight aggregates may or may not become essentially filled with water after immersion for 24 h. In fact, many such aggregates can remain immersed in water for several days without satisfying most of the aggregates’ absorption potential. Therefore, this test method is not intended for use with lightweight aggregate.

- The knowledge of the specific gravity is important for the concrete technologist to determine the properties of concrete made from such aggregates.

- It is used for the calculation of the volume occupied by the aggregates in various mixtures and generally it ranges from 2.5-3.

- The pores at the surface of the particles affect the bond between the aggregate and the cement paste and thus influence the concrete strength. Smaller the number of pores, higher will be the specific gravity and hence more will be the bond strength and more concrete strength.

- Normally it is assumed that at the time of setting of concrete, the aggregate is in the saturated and surface dry condition. If the aggregate is to be batched in the dry condition, then it is assumed that sufficient amount of water will be absorbed from the mix to bring the aggregate in the saturated condition. If an additional amount of water is not added as a cover for the absorbed water, the loss of workability is resulted.

- Though higher specific gravity of aggregate is considered as an indication of its high strength; it is not possible to judge the suitability on this basis alone without finding other mechanical properties like aggregate abrasion value etc.

- Water absorption is a measure of porosity of aggregates and its resistance to frost action.

- Higher water absorption means more pores, hence aggregate will be the considered as weak.

- Water absorption value ranges from 0.1 – 2.0% for aggregate normally used in roads surfaces.

- Aggregates with water absorption up to 4.0% are acceptable in base coarse

Related theory:

Aggregates:

Aggregates may be classified as;

- Coarse Aggregates

- Fine Aggregates

Coarse aggregates:

Any material which is retained on ASTM sieve 4.75mm/ BS sieve #4 is known as coarse aggregate.

Fine aggregates:

Any material which is passing ASTM sieve 4.75mm/ BS sieve #4 is known as fine aggregate.

Types of crush available in Pakistan

Sargodha crush:

Sargodha crush possess the following properties;

- Greenish/Dark grey in color

- High strength

- Usually elongated particles

Margalla crush:

Margalla crush possess the following properties;

- Grayish in color

- Low in strength

Sakhi sarwar crush:

Sakhi Sarwar crush possess the following properties;

- Whitish in color

- Moderate strength

Oven-dry (OD):

“The condition in which the aggregates have been dried by heating in an oven at 110 ± 5°C for sufficient time to reach a constant mass”.

Saturated surface dry (SSD) condition:

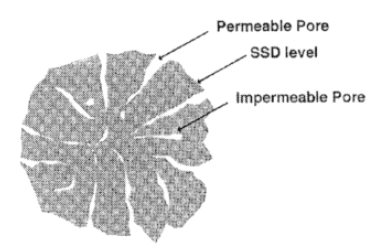

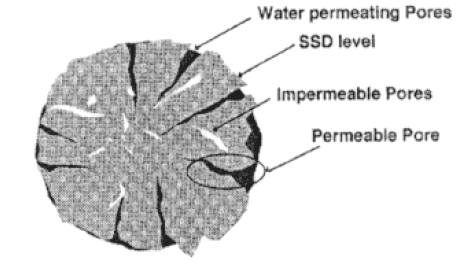

“It is the condition related with the aggregate particles in which the permeable pores of the aggregate particles are filled with water but without free water on the surface of the particles”.

Specific gravity/Relative density:

“It is the ratio of the density of the aggregate material to the density of the gas free distilled water at a standard temperature (i.e. 4 oC)”.

The relative density is a dimensionless quantity and is expressed as oven dried, saturated surface dry and apparent specific gravities.

Bulk specific gravity (Oven dried):

“It is the ratio of the oven dried density of the aggregate (including the permeable and impermeable voids in the particles, but not including the voids between particles) to the density of the gas free distilled water at a standard temperature (i.e. 4 oC)”.

(Bulk specific gravity condition)

Bulk specific gravity (Saturated surface dry):

“It is the ratio of the saturated surface dry density of the aggregate (including the weight of water within the voids filled to the extent achieved by submerging in water for approximately 24 h but not including the voids between particles) to the density of the gas free distilled water at a standard temperature (i.e. 4 oC)”.

(Saturated surface dry condition)

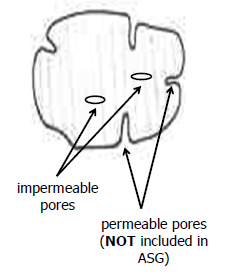

Apparent specific gravity

“It is the ratio of the apparent density of the aggregate to the density of the gas free distilled water at a standard temperature (i.e. 4 oC)”.

(Apparent specific gravity condition)

Absorption:

“It is the increase in the mass of the aggregate due to the penetration of water in the pores of the particles during a prescribed period of time”.

The term absorption does not include the amount of water adhering to the surface of the particles. Water absorption is expressed as percentage of the dry mass.

Apparatus:

- Weighing Balance

- Sample container in the form of wire mesh bucket of capacity 4000-7000 cm3 and not more than 6.3mm mesh.

- Suitable arrangement for suspending the container in water from center of the balance

- Container for filling water and suspending the wire mesh bucket

- Shallow tray and absorbent cloth

- Oven

- Sample of aggregate

Procedure:

Sampling:

- Take representative sample.

- Reject all material passing a 4.75-mm (No. 4) sieve by dry sieving and thoroughly wash to remove dust or other coatings from the surface

The minimum weight of test sample to be used is given below.

| Nominal Maximum Size, mm (in.) | Minimum Weight of Test Sample, kg (lb) |

| 12.5 (1⁄2) or less | 2 (4.4) |

| 19.0 (3⁄4) | 3 (6.6) |

| 25.0 (1) | 4 (8.8) |

| 37.5 (1 1⁄2) | 5 (11) |

| 50 (2) | 8 (18) |

| 63 (2 1⁄2) | 12 (26) |

| 75 (3) | 18 (40) |

| 90 (3 1⁄2) | 25 (55) |

| 100 (4) | 40 (88) |

Test procedure:

- Dry the sample to a constant weight at a temperature of 100 ± 50

- Cool the sample at room temperature for about 1 – 3 hrs. and then immerse in water at room temperature for 24 ± 4 hrs.

- Remove sample from water and wipe the particles using absorbent cloth until all surface films are removed.

- Weigh the sample in this saturated surface dry condition to the nearest 0.5 g.

- Immediately after weighing, place the sample in a wire basket, suspend in water at 23 ± 1.70C, and obtain the buoyant weight.

- Take care to remove all entrapped air before weighing by shaking the container while immersed.

- Dry the test sample to constant weight at a temperature of 110 ± 5°C, cool in air at room temperature for 1 to 3 h, or until the aggregate has cooled to a temperature that is comfortable to handle (approximately 50°C), and weigh.

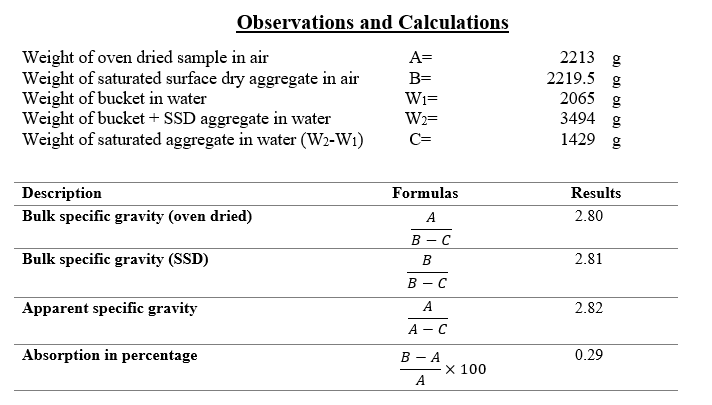

Comments:

The specific gravity of aggregates normally used in road construction ranges from about 2.5 to 3.0 with an average value of about 2.68. Water absorption value ranges from 0.1 to about 2.0 percent for aggregates normally use in road surfacing.

Specific gravity of aggregates is considered as an indication of strength. Material having higher specific gravity is generally considered as having higher strength. Water absorption of aggregate is a measure of porosity. This value is considered as a measure of resistance to frost action, and as a measure of sustaining weathering action.