Lab 2:

Determination of initial and final setting time of hydraulic cement

(ASTM C 191-04 a, BS-4550, JIS-R5201)

Significance:

- To know about the time limit in which we can work upon cement paste.

- To know final setting time to remove shuttering.

Apparatus:

- Devices for Determining Mass

- Glass Graduates, 200 or 250-mL capacity

- Flat Trowel

- Cement 650g (according to standard)

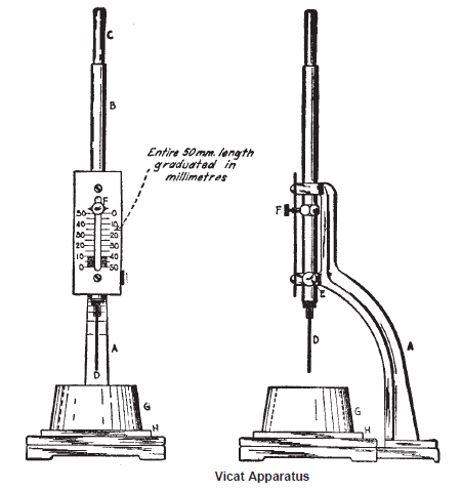

- VICAT Apparatus

Specifications of VICAT apparatus:

- Frame

- Movable rod, of mass 300 ±5g.

- Plunger end

- The end of the rod used for measuring penetration shall have a straight steel removable needle with a diameter of 1.00 ±05 mm and length not less than 50 mm.

- The rod, B, is reversible, and can be held in any desired position by a setscrew, E

- It is an adjustable indicator which moves over a scale graduated in millimeters and attached to the frame

- The paste is held in a rigid conical ring. made of a rigid, non-corroding, nonabsorbent material and having a height of 40 ± 1 mm, an inside diameter at the bottom of 70 ± 3 mm, and an inside diameter at the top of 60 ± 3 mm

- The ring is resting on a plane non-absorptive square base plate

Related theory:

Setting:

It is the measure of gain of stiffness of the cement paste. At this level paste acquires stable shape and volume and does not flow under its weight on a mild slope surface.

In the setting process little chemical reaction takes place. It only includes the shape acquisition due to evaporation of water. During the setting process the cement remains in the fluid or the semi-fluid state and there is very little or no gain in strength. Finer the cement particles more will be the hydration and therefore it will lead to quick settlement.

Hardening:

Hardening is the rate of gain of strength due to the chemical reaction. It also refers to the strength of the concrete after a specified interval of time. It can take little load and will maintain its acquired shape.

Initial setting time/ VICAT time of initial setting:

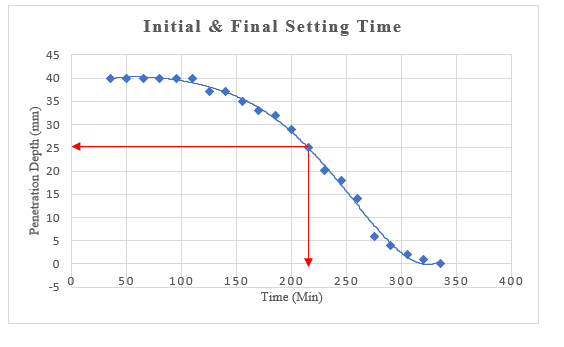

It is the time elapsed between the start of mixing of water in the cement to the condition of cement paste such that 1 mm diameter needle of VICAT apparatus penetrates into the paste by 25 mm

Final setting time/ VICAT time of final setting:

It is the time from start of mixing (when water is added) till the condition of paste such that it is the first penetration measurement that does not mark the specimen surface with a complete circular impression

Procedure:

Molding Test Specimen—Quickly form the cement paste, into a ball with gloved hands and toss six times from one hand to the other, maintaining the hands about 150 mm (6 in.) apart. Press the ball, resting in the palm of the hand, into the larger end of the conical ring, G, held in the other hand, completely filling the ring with paste. Remove the excess at the larger end by a single movement of the palm of the hand. Place the ring on its larger end onto the non-absorptive plate, H, and slice off the excess paste at the smaller end at the top of the ring by a single oblique stroke of the trowel held at a slight angle with the top of the ring. Smooth the top of the specimen, if necessary, with one or two light touches of the pointed end of the trowel.

During the operation of cutting and smoothing, take care not to compress the paste. Immediately after molding, place the test specimen in the moist cabinet or moist room and allow it to remain there except when penetration measurements are being made. The specimen shall remain in the conical mold, supported by the non-absorptive plate throughout the test period.

Time of Setting Determination—Allow the time of setting specimen to remain in the moist cabinet or moist room for 30 min after molding without being disturbed. Determine the penetration of the 1-mm needle at this time and every 15 min thereafter (every 10 min for Type III cements) until a penetration of 25 mm or less is obtained. Perform the penetration

test by lowering the needle D of the rod B until it rests on the surface of the cement paste. Tighten the setscrew, E, and set the indicator, F, at the upper end of the scale, or take an initial reading. Release the rod quickly by releasing the set screw, E, and allow the needle to settle for 30 s; then take the reading to determine the penetration. At the option of the tester, if the paste is obviously quite soft on the early readings, retard the fall of the rod to avoid bending the 1-mm needle, but when actual penetration measurements to determine the time of setting are made, release the rod only by the setscrew. Make each penetration test at least 5 mm away from any previous penetration and at least 10 mm away from the inner side of the mold.

Record the results of all penetration tests and, by interpolation, determine the time when a penetration of 25 mm is obtained. The elapsed time between the initial contact of cement and water and the penetration of 25 mm is the VICAT time of setting or VICAT initial time of setting.

Determine the VICAT final time of setting end point to be the first penetration measurement that does not mark the specimen surface with a complete circular impression. Verify final set by performing two additional penetration measurements on different areas of the specimen surface. Obtain verification measurements within 90 s of the first “final set” measurement. The elapsed time between the initial contact of cement and water and the end point determination above is the VICAT final time of setting.

Temperature and Humidity:

- The temperature of the air in the vicinity of the mixing slab, the dry cement, molds, and base plates shall be maintained between 20 and 27.5 °C (68 and 81.5 °F).

- The temperature of the mixing water shall not vary from 23.0 °C (73.5 °F) by more than 62.0 °C (3.5 °F).

- The relative humidity of the laboratory shall be not less than 50 %.

Precautions:

- Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and tissue upon prolonged exposure. The use of gloves, protective clothing, and eye protection is recommended.

- Wash contact area with copious amounts of water after contact. Wash eyes for a

minimum of 15 min.

- Avoid exposure of the body to clothing saturated with the liquid phase of the unhardened material. Remove contaminated clothing immediately after exposure

- The apparatus should be free from vibrations during all the test.

Observations and Calculations

Type of cement: Ordinary Portland Cement

Manufacturer: Maple leaf

Room temperature = 16°C

%age of added water = 25% (normal consistency)

Weight of mixing sample = 500g

| Sr# | Description | Time Interval | Time Elapsed | Penetration |

| min | min | mm | ||

| 1 | Addition of water in cement | 0 | – | |

| 2 | Mixing & filling of mold | 5 | 5 | |

| 3 | 1st Reading | 30 | 35 | 40 |

| 4 | 2nd Reading | 15 | 50 | 40 |

| 5 | 3rd Reading | 15 | 65 | 40 |

| 6 | 4th Reading | 15 | 80 | 40 |

| 7 | 5th Reading | 15 | 95 | 40 |

| 8 | 6th Reading | 15 | 110 | 40 |

| 9 | 7th Reading | 15 | 125 | 37 |

| 10 | 8th Reading | 15 | 140 | 37 |

| 11 | 9th Reading | 15 | 155 | 35 |

| 12 | 10th Reading | 15 | 170 | 33 |

| 13 | 11th Reading | 15 | 185 | 32 |

| 14 | 12th Reading | 15 | 200 | 29 |

| 15 | 13th Reading | 15 | 215 | 25 |

| 16 | 14th Reading | 15 | 230 | 20 |

| 17 | 15th Reading | 15 | 245 | 18 |

| 18 | 16th Reading | 15 | 260 | 14 |

| 19 | 17th Reading | 15 | 275 | 6 |

| 20 | 18th Reading | 15 | 290 | 4 |

| 21 | 19th Reading | 15 | 305 | 2 |

| 22 | 20th Reading | 15 | 320 | 1 |

| 23 | 21st Reading | 15 | 335 | 0 |

Results:

Initial setting time = 220 min (3.67 hrs)

Final setting time = 335 min (5.58 hrs)

Comments:

- The test specifications as described by ASTM C 191-04a were not fully met in the laboratory experiment due to that the initial and final setting times as obtained from the experiment are not the standard ones.

- The temperature was the main cause of error. Firstly, it was not the standard temperature, also it fluctuated during the performance of experiment.

- More amount of water was added due to which the setting time was increased and temperature of laboratory was also less.