Job # 1:

Determination of Flakiness and Elongation Index of given aggregate sample

Scope & Significance:

This test is used to determine the particle shape of the aggregate and each particle shape being preferred under specific conditions. The significance of flakiness & elongation index is as follows;

- The degree of packing of the particles of one size depends upon their shape.

- Due to high surface area to volume ratio, the flaky and elongated particles lower the workability of concrete mixes.

- Flaky and elongated particles are considered undesirable for base coarse construction as they may cause weakness with possibilities of breaking down under heavy loads.

- BS-1241 specifies a Flakiness index not exceeding 30% irrespective of the aggregate size.

- Maximum permitted Elongated index is 35 for aggregate sizes 2 ½’’ – 2’’, 40 for aggregate sizes 1 ½’’ – ¾’’ and 45% for aggregate sizes ½’’ – 3/8’’.

- Both Flakiness and Elongation tests are not applicable to sizes smaller then 6.3mm i.e. ¼’’ sieve.

Related theory:

Shapes of particles:

The usual shapes of the particles are;

- Rounded (river gravel)

- Angular (crushed rock)

- Flaky (laminated rock)

- Elongated

Use of different particles shapes:

- Round aggregates are preferred in concrete roads (rigid pavements) as the workability of concrete increases due to the less friction between the surfaces.

- Angular aggregates are desirable in granular base coarse (flexible pavement) due to better interlocking and increased stability.

- Flaky and elongated aggregates are considered as a source of weakness.

Shape tests:

The particle shape of aggregate is determined by the percentage of flaky and elongated particles contained in it. In case of gravel it is determined by its angularity number. For base course and construction of bituminous and cement concrete types, the presence of flaky and elongated particles are considered undesirable as they may cause inherent weakness with possibilities of breaking down under heavy loads. Rounded aggregates are preferred in cement concrete road construction as the workability of concrete improves. Angular shape of particles is desirable for granular base course due to increased stability derived from the better interlocking. When the shape of aggregates deviates more from the spherical shape as in the case of angular, flaky and elongated aggregates, the voids content in an aggregate of any specified size increases and hence the grain size distribution of a grade aggregate has to be suitably altered in order to obtain minimum voids in the dry mix or the highest dry density. The angularity number denotes the void content of the same size. Thus, angularity number has considerable importance in the gradation requirements of various types of mixes such as bituminous concrete and soil-aggregate mixes.

Thus, evaluation of shape of the particles, particularity with reference to flakiness, elongation and angularity is necessary.

Flaky particles:

“A flaky particle is the one whose least dimension (thickness) is less than 0.6 times the mean size”

These are the particles of which the thickness is small as compared to the other two dimensions.

Limit of flaky particles in the mixes is 30%.

If the flaky particles are greater than 30% then the aggregate is considered undesirable for the intended use.

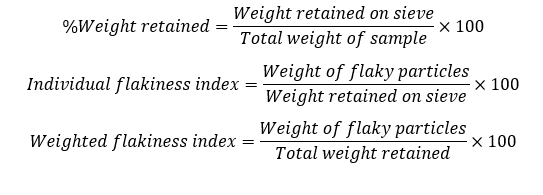

Flakiness index:

It is the percentage by weight of flaky particles in a sample. The Flakiness index is calculated by expressing the weight of flaky particles as a percentage of the total weight of sample

Elongated particles:

“An elongated particle is the one whose greater dimension is 1.8 times its mean size”

These are the particles having length considerably larger than the other two dimensions.

Limit of elongated particles in the mixes is 45%.

If the elongated particles are greater than 45%, then the aggregate is considered undesirable for the intended use.

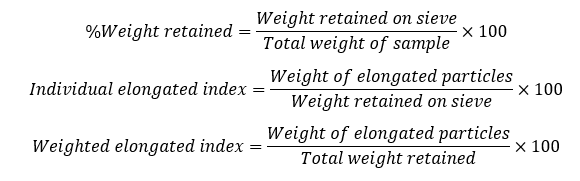

Elongated index:

It is the percentage by weight of elongated particles in a sample. The Elongated index is calculated by expressing the weight of Elongated particles as percentage of total weight of the sample.

Apparatus:

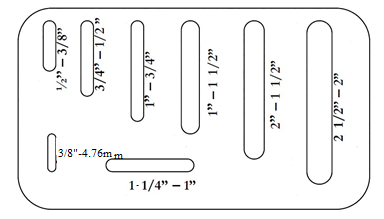

- Thickness/Flakiness Index Gauge

- Length/Elongation Index Gauge

- Aggregate sample

- Coarse sieve shaker

- Weighing balance

Procedure for determining Flakiness index of aggregate sample:

Flakiness index gauge

- Perform sieve analysis on aggregate sample using coarse sieve shaker.

- Weigh the sample retained on each sieve

- Make the groups of the weighed samples according to their particle size i.e the particles that retained on sieves 1.5”, 1”, ¾”, ½”, 3/8”, 4.76mm.

- Each group is tested for thickness on appropriate opening of the thickness gauge by passing each particle through slot of specified thickness along least dimension.

- The weight of particles passing the thickness gauge is recorded for each fraction.

- This will be the weight of flaky particles.

- The flakiness index is calculated by expressing the weight of flaky particles as a percentage of total weight of the sample.

The expressions used in table are given below:

Observations and calculations

| Sieve Size | Weight Retained on sieve | % Weight retained | Wt. of Flaky Particles (passing through sieves) | Individual Flakiness Index | Weighted Flakiness Index | |

| Passing | Retained | gm | % | gm | % | % |

| 2.5″ | 1.5″ | 0 | 0.00 | 0 | 0.00 | 0.00 |

| 1.5″ | 1″ | 0 | 0.00 | 0 | 0.00 | 0.00 |

| 1″ | 3/4″ | 2370.6 | 37.02 | 507.5 | 21.41 | 7.92 |

| 3/4″ | 1/2″ | 3167 | 49.45 | 536.6 | 16.94 | 8.38 |

| 1/2″ | 3/8″ | 683.7 | 10.68 | 166 | 24.28 | 2.59 |

| 3/8″ | ¼” | 182.6 | 2.85 | 45 | 24.64 | 0.70 |

| Summation | 6403.9 | 19.60 | ||||

Result:

Flakiness index of aggregate sample = 19.60 %

Comments:

As the flakiness index is less than 30%, hence aggregate is considered desirable for use.

Procedure for determining Elongation index of aggregate sample:

Elongation index gauge

- Perform sieve analysis on aggregate sample using coarse sieve shaker.

- Weigh the sample retained on each sieve

- Make the groups of the weighed samples according to their particle size i.e the particles that retained on sieves 1.5”, 1”, ¾”, ½”, 3/8”, 4.76mm.

- Each group is tested for length on appropriate opening in the length gauge.

- The weight of particles which don’t pass through the specified gauge length with its long side are separated and recorded for each fraction.

- This will be the weight of elongated particles.

- The elongated index is calculated by expressing the weight of flaky particles as a percentage of total weight of the sample.

The expressions used in table are given below:

Observations and calculations

| Sieve Size | Weight Retained

on sieve |

% Weight Retained | Weight of Elongated Particles (don’t passing through gauge length) | Individual Elongated Index | Weighted Elongated Index | |

| Passing | Retained | gm | % | gm | % | % |

| 2.5″ | 1.5″ | 0 | 0.00 | 0 | 0 | 0.00 |

| 1.5″ | 1″ | 0 | 0.00 | 0 | 0 | 0.00 |

| 1″ | 3/4″ | 2370.6 | 37.02 | 497 | 20.97 | 7.76 |

| 3/4″ | 1/2″ | 3167 | 49.45 | 1765 | 55.73 | 27.56 |

| 1/2″ | 3/8″ | 683.7 | 10.68 | 420 | 61.43 | 6.56 |

| 3/8” | ¼” | 182.6 | 2.85 | 140 | 76.67 | 2.19 |

| Summation | 6403.9 | 44.07 | ||||

Result:

Elongated index of aggregate sample = 44.07 %

Comments:

As the elongated index is less than 45%, hence aggregate is considered desirable for use.