Lab 5:

Determination of bulk density of aggregates:

(ASTM C-29/C-29M)

Significance:

- This test method is used to determine the bulk density of the given specimen.

- During the concrete mix design, when the aggregate is to be batched by volume or by weight, then it becomes necessary to know the mass of the aggregates that will fill the container of unit volume. If we know the bulk density of the aggregate material then we can easily determine the mass required to fill a unit volume container.

- Bulk density also indicates the percentage of voids present in the aggregate material. This percentage of voids affects the grading of the aggregates which is important in high strength concrete.

- Bulk density also indicates the compactive effort required to compact the concrete.

- More is the density more will be the well graded material

Apparatus:

- Weighing Balance

- Temping rod

- Measuring Cylinders

- Shovel or Scoop

- Fine and coarse aggregate

Related theory:

Bulk density:

“It is the mass of the unit volume of bulk aggregate material”.

The term volume includes the volume of the individual particles and the volume of the voids between the particles.

Bulk density is used in weight and volume batching.

Voids:

“It is the space between the individual particles in a unit volume of the aggregate mass and is not occupied by the solid mineral matter”.

Voids within the particles, either permeable or impermeable are not included in the voids for the determination of bulk density by this method.

Absolute density:

“It is the mass per unit volume of the individual particles only”.

Facts about bulk density

Bulk density depends upon how densely the aggregate is packed. It also depends upon the size, distribution and shape of the particles. If the particles are of the same size, then it can be packed to a limited extent but when the smaller particles are added, the voids get filled with them and thus the bulk density increases.

For a coarse aggregate, a higher bulk density means that there are few voids which are to be filled by the fine aggregate and cement. Thus, bulk density also depends upon the degree of packing.

Procedure:

- Note down the dimensions and empty weight of the measuring container and compute its volume.

- For the determination of the loose bulk density, fill the container with the aggregate material by means of a shovel and level its top surface. Discharge the aggregate from height not greater than 2 inch.

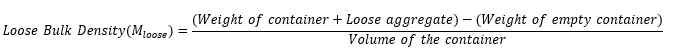

Weigh the container filled with the aggregate and note down its reading. Then the loose bulk density of the aggregate material can be computed by using the relation;

- For the determination of the compacted bulk density, the only difference is in filling the container. In this case, the container is filled in three equal layers. Fill the container about one-third full and level the surface with the fingers. Rod the layer of the aggregate with 25 strokes of the temping rod evenly distributed over the surface. Next fill the container two-third full and again rod it with 25 strokes of the temping rod. Finally, fill the container to overflowing and rod again in the manner previously mentioned.

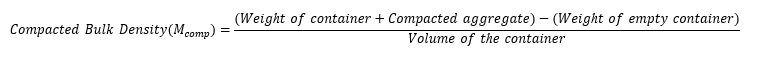

Now level the top surface and weigh the container. Calculate the compacted bulk density by using the relation;

- For the determination of the gigging bulk density, the container is filled in three equal layers. Give 25 number of jerks on each side to each layer.

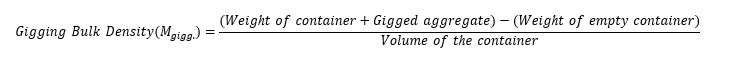

Now level the top surface and weigh the container. Calculate the gigging bulk density by using the relation;

Observations & Calculations

| Description | Values | fps units | Values | SI units |

| Weight of container for coarse aggregate | 16.25 | lbs | 7.37 | kg |

| Volume of container for coarse aggregate | 0.5 | ft3 | 0.0142 | m3 |

| Weight of container for fine aggregate | 5.75 | lbs | 2.60 | kg |

| Volume of container for fine aggregate | 0.1 | ft3 | 0.0028 | m3 |

| Sample | State | Weight of cylinder + aggregate | Weight of aggregate | Volume of container | Bulk density | ||||

| lbs | kg | lbs | kg | m3 | ft3 | kg/m3 | lb/ft3 | ||

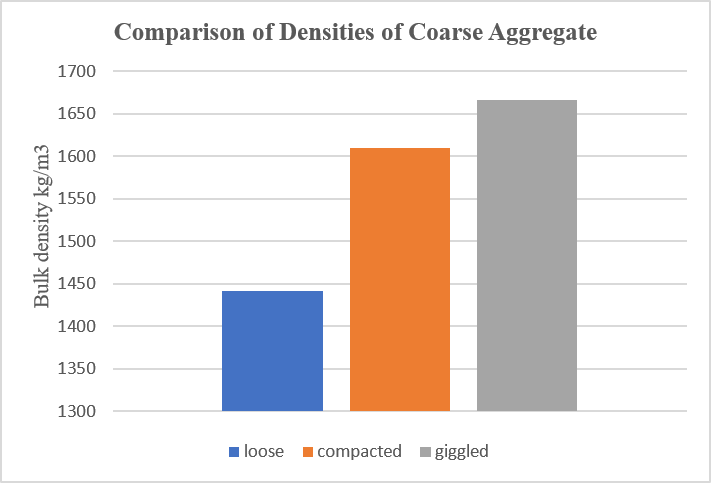

| Coarse aggregate | loose | 61.25 | 27.8 | 45 | 20.4 | 0.0142 | 0.5 | 1441.9 | 90 |

| Coarse aggregate | compact | 66.5 | 30.2 | 50.25 | 22.8 | 0.0142 | 0.5 | 1610.2 | 100.5 |

| Coarse aggregate | gigging | 68.25 | 31.0 | 52 | 23.6 | 0.0142 | 0.5 | 1666.3 | 104 |

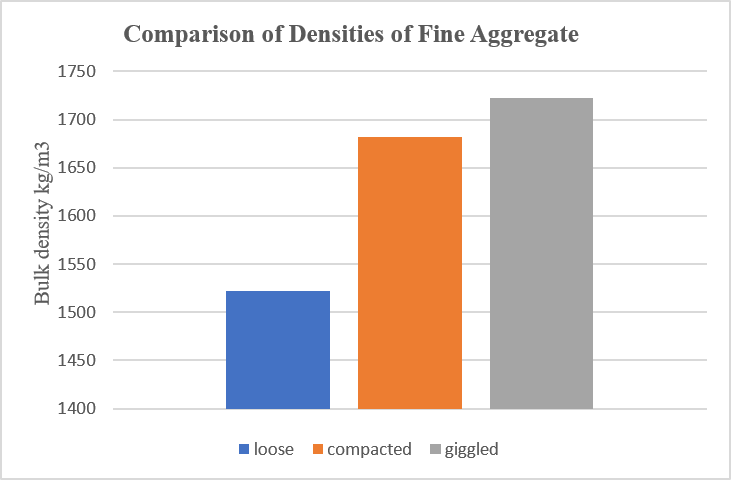

| Fine aggregate | loose | 15.25 | 6.9 | 9.5 | 4.3 | 0.0028 | 0.1 | 1522.1 | 95 |

| Fine aggregate | compact | 16.25 | 7.4 | 10.5 | 4.8 | 0.0028 | 0.1 | 1682.3 | 105 |

| Fine aggregate | gigging | 16.5 | 7.5 | 10.75 | 4.9 | 0.0028 | 0.1 | 1722.3 | 107.5 |

Comments:

From the experiment performed we came to know that the bulk-density of a material in gigging form is greater than the bulk-density of a material in loose form and in rodded form.