Lab 3:

Determination of aggregate impact value (AIV) of given aggregate sample

(BS-812)

Significance:

- Aggregates used in the construction of roads should be strong enough to resist crushing under traffic wheel loads.

- It gives relative measure of the resistance of an aggregate to sudden shock or impact.

- Increase in impact value will indicate reduction in strength of material.

Apparatus:

- Aggregates passing sieve ½” and retained on 3/8” from different sources.

- Aggregate impact value apparatus

- Weighing balance

- Tamping rod

- Sieve # 7 (opening 2.83 mm)

- Brush with stiff bristles

- Drying Oven

- Metal try of known mass

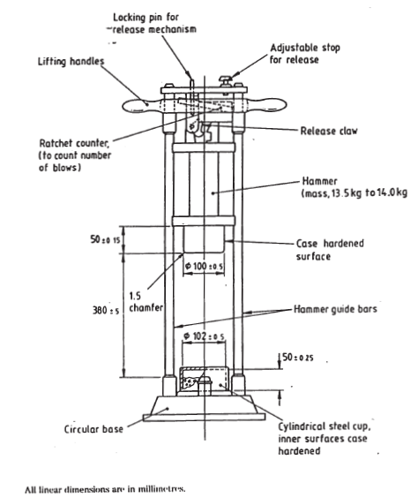

Specifications of impact value apparatus:

Cylindrical container having internal diameter of 75 mm and depth of 50mm

Weight of hammer = 13.5 – 14 kg

Height of fall of hammer = 15”

|

Impact Value Apparatus with its Parts |

Related theory:

Types of tests performed on aggregates:

- Impact value test

- Loss Angeles abrasion test

- Aggregate crushing value

- Soundness test

- Moisture content of aggregate

- Relative density and water absorption

- Sieve tests

- Flakiness index

Aggregate Impact value:

It is the % of fine material which is crushed after the application of load w.r.t. total weight of material.

Test specifications:

The test sample shall consist of aggregates which passes through ½ in B.S. test sieve and is retained on a 3/8 in B.S. test sieve.

The aggregate comprising the test sample should be dried in an oven for a period of four hours at a temperature of 105-110 0C and cooled.

Procedure: (Dry Condition)

- Rest the impact machine, without wedging or packing, upon the level plate, block or floor, so that it is rigid and hammer guide columns are vertical

- Take oven dried sample that passes through sieve ½” and is retained on sieve 3/8”

- Place the sample in the cylindrical container of aggregate impact value apparatus and weigh it. Suppose this value is W

- Remove the sample from container in clean tray.

- Place the sample in cylindrical container of aggregate impact value apparatus in 3 layers.

- Each layer must be given 25 no. of blows

- Each blow being delivered at an interval of not less than 1s

- The hammer should be fall freely for about 15”

- Remove the crushed aggregate by holding the cylinder over a clean tray and hammering on the outside with the rubber mallet until the particles are sufficiently disturbed to enable the mass of specimen to fall freely on tray.

- Transfer fine particles adhering to the inside of the cup and the underside of the hammer to the tray by means of the stiff bristle brush.

- Sieve the whole of specimen in the tray on the 2.36 mm test sieve until no further significand amount passes during a further period of 1 min.

- Weigh the mass that is passed as W2 and that is retained as W

- Now, if total mass differs from the initial mass W1 by more than 1 g, discard the result and test a further specimen.

- Repeat the same procedure for the other samples and note the readings.

- Find the aggregate impact value from the formula given below:

where, W1 is the total mass of sample

W2 is the mass that passes sieve # 7

Observations and calculations

| Sr. no. | Sample Source | Total weight of sample (W1) | Fraction passing sieve # 7 (W2) | Fraction retained on sieve # 7 (W3) | |

| gm | gm | gm | % | ||

| 1 | Margalla | 365 | 53 | 312 | 14.52 |

| 2 | Margalla | 353 | 50 | 303 | 14.16 |

| 3 | Sargodha | 341 | 37 | 304 | 10.85 |

| 4 | Sargodha | 372 | 45 | 327 | 12.10 |

Precautions:

- Care should be taken while giving blows with hammer.

- Aggregates should be oven dried.

- The mass should be noted nearest to 0.1 g.

- The time interval between the blows should not be less than 1s.

Comments:

The aggregates are classified on the basis of their impact value as

| Impact Value | Classification |

| <10% | Exceptionally strong |

| 10 – 20% | Strong |

| 20 – 30% | Satisfactory |

| >30 | Weak |

From the above classification, the given aggregate samples can be classified as Strong Aggregates because their respective impact values are in the range 10 to 20%