Job # 5

To perform tension test on hot rolled deformed steel bar

Objective:

- To determine different mechanical properties of steel

- To study the stress strain behavior of mild steel

- To check the adequacy of specimen according to ASTM standard

Apparatus:

- 500 kN Shimadzu UTM

- Extensometer

- Spring divider

- Vernier calipers

- Weighing balance

- Steel tape

- Hot rolled deformed steel bar

Related theory:

Steel: Steel is an alloy of iron.

Carbon content in steel:

There is a significant effect of carbon content on the properties of resulting steel. The yield strength tends to be higher and the ductility tends to be lower with the increase of carbon content.

| Type of steel | Carbon content |

| Low carbon steel | 0.05 – 0.25 |

| Mild steel | 0.16 – 0.29 |

| Medium carbon steel (MS) | 0.3 – 0.59 |

| High carbon steel | 0.6 – 0.99 |

| Ultra high carbon steel | 1 – 2 |

| Cast iron | 2 – 5 |

Types of steel bars:

- Plane steel bar

- Hot rolled deformed steel bar

- Cold worked/cold twisted/tor bar

Components of stress strain diagram:

- Proportional limit: (P) the maximum stress that may be developed during a simple tension test such that the stress is linear function of strain. There is no proportional limit for brittle materials.

- Elastic limit: (E) the maximum stress that may be developed during a simple tension test such that there is no permanent deformation when the load is entirely removed. Hooks law is not valid after E.L.

- Yielding: increase in strain without the corresponding increase in stress is called yielding. This may occur in certain types of materials such as mild steel just after the elastic limit.

- Upper yield point: (U) this is a point at which there is a sudden drop in stress (or load) with further strain.

- Lower yield point: (L) it is a point after which there is a significant extension at almost constant load.

- Strain hardening or work hardening: after the completion of initial yielding, the stress again starts increasing with the increase of the strain up to a peak point on the stress strain curve. This behavior is call strain hardening and the material becomes harder in this zone.

- Ultimate tensile strength: maximum value of stress on stress strain diagram is called ultimate tensile strength. It is the point where the slope of the curve becomes zero. It is commonly considered as the maximum strength of the material.

- Necking: localized decrease in the cross sectional area of the sample after the ultimate strength is called necking. This continues up to rupture/failure.

- Fracture or rupture: this is the final point on stress strain curve at which the specimen breaks by a cup and cone formation. It is always less than the ultimate strength. For brittle materials the ultimate and rupture strength are almost same.

- Plasticity: it is the ability of a material to be permanently deformed by the application of load. The work done on the material within this range is not stored as a potential energy but is converted into heat and is dissipated to the environment.

- Elastic range: when the specimen is loaded up to the elastic limit and all the strains are recovered upon unloading, the material is said to be in elastic range. In this zone all the work done on the specimen is stored as potential energy, which brings specimen beck to its original shape after the removal of load.

- Resilience: the ability of a material to absorb energy in the elastic range (i.e without permanent deformation) is called resilience.

- Modulus of resilience: it is the amount of work done on a unit volume of material as a simple tensile force is increased from 0 to proportional limit. It is calculated as the area under the stress strain diagram from 0 to P.L.

- Toughness: the ability of a material to absorb energy in the plastic range (i.e. permanent deformation) is called toughness.

- Modulus of toughness: it is the amount of work done on a unit volume of material as a simple tensile force is increased from 0 to the failure of the specimen. It is calculated as the total area under the stress strain diagram.

- Measures of ductility:

- % elongation

- % decrease in area of cross section

All ductile materials are stronger in tension and compression but weak in shear.

All brittle materials are weak in tension and compression but strong in shear.

- Methods of determining yield strength:

- Halting of machine method:

The stress may actually decrease momentarily resulting in upper and lower yield points. The yield point during a simple tension test can be observed by Halting of machine.

- Offset method:

For the materials that do not gave well-defined yield point, yield strength is determined by offset method. This consists of drawing a line parallel to the initial tangent of the stress strain diagram at0.2% (0.002 m/m or in/in) strain.

- Luderline method:

When the specimen yields, a pattern of fine lines appears on the polished surface, they roughly interact at right angle to each other and 45 degrees approximately to the longitudinal axis of the bar.4.

- Specific strain method

In this method simply 0.5% of the total strain is marked to determine the corresponding stress, which is yielding stress

Procedure:

- Measure the dimensions of a specimen Diameter, Total length of a specimen, Cross sectional area Mark gage length at three different portions on the specimen, covering effective length of a specimen.(this is required so that necked portion will remain between any two points of gage length on the specimen.)

- Grip the specimen in the fixed head of a machine. (Portion of the specimen has to be gripped as shown in the fig.7.

- Fix the extensometer within the gauge length marked on the specimen. Adjust the dial of extensometer at zero.

- Adjust the dial of a machine to zero, to read load applied.

- . Select suitable increments of loads to be applied so that corresponding elongation can be measured from dial gauge.

- . Keep speed of machine uniform. Record yield point, maximum load point, point of breaking of specimen.

- Remove the specimen from machine and study the fracture observes type of fracture.

- Measure dimensions of tested specimen. Fit the broken parts together and measure reduced diameter and final gage length.

Gauge length:

Length of the cylindrical portion of the test sample on which elongation is to be measured at any moment during the test.

- Extensometer gauge length (Le)

- Original gauge length (L0)

- Final gauge length (LU)

Elongation:

Increase in the original gauge length L0 at the end of the test.

Extension:

Increase in the extensometer gauge length Le at a given moment of the test.

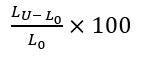

Percentage elongation:

Elongation expressed as a % of the original gauge length

Neck area:

The reduced area of cross section at the point of breaking.

% reduction of an area:

Ratio of maximum change in cross sectional area which has occurred during the test to the original cross sectional area.

Observations and calculations

Specimen measurements

Original Length = 45.3 cm = 0.453 m

Mass = 445 g = 0.445 kg

Density = 7850 kg/m3

Density = mass/volume

From this equation

=original cross sectional area= 1.25 * 10-4 m2 =125 mm2

Hence actual D = 12.61 * 10-3 m

Gauge length = 50 mm

| Load

(P) |

Extensometer/

Spring divider reading |

Elongation | % strain

=

|

Stress= | Remarks |

| N | mm | MPa | |||

| 0 | 0 | 0 | 0 | 0 | Elastic zone |

| 5 | 4 | 0.004 | 0.008 | 0.04 | |

| 10 | 9 | 0.009 | 0.018 | 0.08 | |

| 15 | 11 | 0.011 | 0.022 | 0.12 | |

| 20 | 14 | 0.014 | 0.028 | 0.16 | |

| 25 | 17 | 0.017 | 0.034 | 0.2 | |

| 30 | 23 | 0.023 | 0.046 | 0.24 | |

| 35 | 31 | 0.031 | 0.062 | 0.28 | |

| 40 | 41 | 0.041 | 0.082 | 0.32 | |

| 45 | 50 | 0.050 | 0.1 | 0.36 | |

| 50 | 59 | 0.059 | 0.118 | 0.40 | |

| 55 | 69 | 0.069 | 0.138 | 0.44 | |

| 60 | 89 | 0.089 | 0.178 | 0.48 | |

| 65 | 101 | 0.101 | 0.202 | 0.52 | |

| 70 | 114 | 0.114 | 0.228 | 0.56 | Yielding zone start |

| 74.5 | 890 | 0.890 | 1.78 | 0.596 | Strain hardening zone start |

| 75 | 905 | 0.905 | 1.81 | 0.6 | |

| 78 | 1216 | 1.216 | 2.432 | 0.624 | |

| 80 | 1419 | 1.419 | 2.838 | 0.64 | |

| 82 | 1666 | 1.666 | 3.332 | 0.656 | |

| 84 | 1970 | 1.970 | 3.94 | 0.672 | |

| 86 | 2350 | 2.350 | 4.7 | 0.688 | |

| 86.7 | 2500 | 2.500 | 5 | 0.6936 | |

| 88 | 54-50=4 | 8 | 0.704 | ||

| 89 | 55-50=5 | 10 | 0.712 | ||

| 90 | 57-50=7 | 14 | 0.72 | ||

| 91 | 57.5-50=7.5 | 15 | 0.728 | ||

| 91.5 | 0.732 | Ultimate tensile strength reached and necking zone started | |||

| 67.2 | 0.5376 | Fracture/breaking load |

Results:

After rupture or fracture the diameter becomes

D of cup = 8.50 mm

D of cone = 9 mm

Davg = 8.75 mm

Rupture area = 60 mm2

Modulus of elasticity =

Nominal breaking stress =

=

Actual breaking stress =

=

% elongation =

=

% reduction in area =