Lab 4:

To perform sieve analysis and to determine fineness modulus of aggregate samples

(ASTM C 136-05), (ASTM C-117-04)

Significance:

- This test method covers the determination of the particle size distribution of fine and coarse aggregates by sieving

- Gradation of material can be determined

- Fine and coarse materials are identified

- The data may be useful for developing relationships concerning porosity and packing

- We can know about the workability and quality of concrete

- In mixed design, fineness modulus is required

- Fineness modulus tells us directly whether the material is well-graded or gap-graded.

- Fineness modulus gives us an overall idea whether the material is fine or coarse.

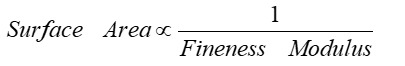

- It also indicates the surface area of the particles.

- Lower the surface area of the aggregate, the required amount of fresh cement paste to cover the aggregate particles will be less and thus less water is required.

- Larger value of FM is preferred for fine aggregates. For a good fine aggregate, the FM should be between 3 and 3.1 (ASTM Range for fine aggregates).

Apparatus:

- Weighing balance

- Standard set of Sieves

- Aggregate sample (fine and coarse)

- Mechanical sieve shaker

- Drying oven

Related theory:

Sieve analysis:

“It is the operation of dividing the aggregate into various fractions, each consisting of particles of same size”.

OR

“It is the operation of determining the particle size distribution of the given specimen”.

The standard approach is to designate the sieve sizes by nominal aperture sizes in mm or μm (micron).

1 mm = 1000 μm (micron)

Notes:

- 5 mm (4.75mm exactly) is the dividing line between coarse and fine aggregate.

- Well graded coarse aggregates of large size will reduce shrinkage of concrete by 50%.

Functions of sieve analysis

Sieve analysis is performed on coarse and fine aggregates in order to check their gradation. This gradation gives an indirect measure if the workability and average particle size.

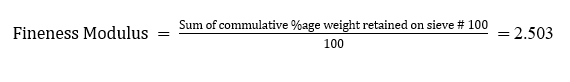

Fineness modulus

It is the cumulative percentage retained on standard sieve 150μm and above divided by 100.

It is a single factor or an empirical number which we get from the results of sieve analysis. The value of FM will not change if we add sieves above.

Set of sieves

The set of sieves used for the process of sieve analysis can be categorized as;

Sieves sizes for gradation of coarse aggregates

| Standard | Non-Standard |

| 75mm (3 ”) | |

| 63mm | |

| 50mm | |

| 37.5mm (1½ ”) | |

| 25mm | |

| 19mm (3/4 ”) | |

| 9.5mm (3/8 ”) | |

| 4.75mm (3/16 ”) | |

| 2.36mm (3/32 ”) | |

| Pan | |

| Note: For sieves with openings 4.75mm & larger, the quantity retained in kg shall not exceed the product of

2.5 x sieve opening (mm) x effective sieving area (mm2) |

|

Sieves sizes for gradation of fine aggregates

| ASTM Sieves

(mm) |

British Standard Sieves

(inches) |

| 4.75mm | 3/16 (#4) |

| 2.36mm | 3/32 (#8) |

| 1.18mm | 3/64 (#16) |

| 600μm | 3/128 (#30) |

| 300μm | 1/88 (#50) |

| 150μm | 1/176 (#100) |

| Pan | Pan |

| Note: For the sieves with openings smaller than 4.75mm, the quantity retained on any sieve at the completion of sieving shall not exceed 7 kg/m2 of sieving area. | |

Quality of a good sample

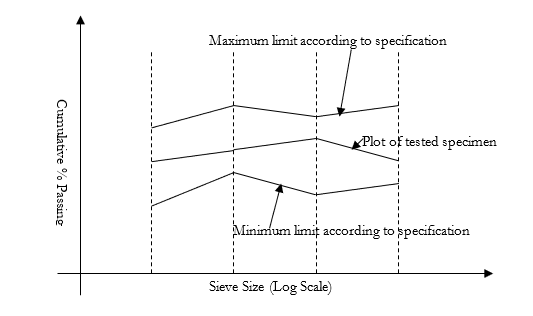

There are some limiting values for every sieve provided by ASTM or BS, we use these limiting values to get our final answer by the method explained below.

Take the minimum and the maximum values provided by ASTM and plot them on the grading curve. Now take these minimum and maximum value lines as your reference and if the curve of our own data lies inside these two lines then the quality of our sample is OK but if your curve lies outside these two lines of maximum and minimum range then the sample is not according to specifications.

ASTM grading requirements for fine aggregates

| Sieve Size | Percentage Passing | |

| Minimum | Maximum | |

| 9.5mm | 100 | 100 |

| 4.75mm | 95 | 100 |

| 2.36mm | 80 | 100 |

| 1.18mm | 50 | 85 |

| 600μm | 25 | 60 |

| 300μm | 10 | 30 |

| 150μm | 2 | 10 |

ASTM grading requirements for coarse aggregates

| Sieve Size

(mm) |

Percentage Passing | |||||

| 37.5mm Down | 19.0mm Down | 12.5mm Down | ||||

| Minimum | Maximum | Minimum | Maximum | Minimum | Maximum | |

| 50 | 100 | 100 | – | – | – | – |

| 37.5 | 95 | 100 | – | – | – | – |

| 25 | – | – | 100 | 100 | – | – |

| 19 | 35 | 70 | 90 | 100 | 100 | 100 |

| 12.5 | – | – | – | – | 90 | 100 |

| 9.5 | 10 | 30 | 20 | 55 | 40 | 70 |

| 4.75 | 0 | 5 | 0 | 10 | 0 | 15 |

| 2.38 | – | – | 0 | 5 | 0 | 5 |

Procedure:

- Take 5 kg of the oven-dried sample. The sample should be perfectly dry because if there is some moisture content present then the particles will stick together and will not pass through the sieves.

Temperature of the oven = 110±5 °C

- Place the set of standard and non-standard sieves one above another with the smallest aperture opening at the bottom. The pan is placed at the bottom-most position. This experiment can be performed manually or with the aid of a machine called “sieve shaker”.

- The manual method should be performed in a proper sequence which is as follows;

- Forward and backward motion

- Left and right motion

- Clockwise (CW) and counter-clockwise (CCW) motion

- Frequent jolting.

Time elapsed for the sieving process is 3-5 minutes.

Weigh the mass retained on each sieve and calculate the percentage passing through each sieve. Then the FM can be calculated by using the relation;

Following points must be kept in mind while calculating the FM;

- Only sum up the values of standard sieves and do not include the values of the non-standard sieves.

- Only add the sieves of 150μm and above sizes.

- If any standard sieve is missing, we may use the value of next higher sieve.

- Adding extra sieves does not change the result of FM.

Observations & Calculations

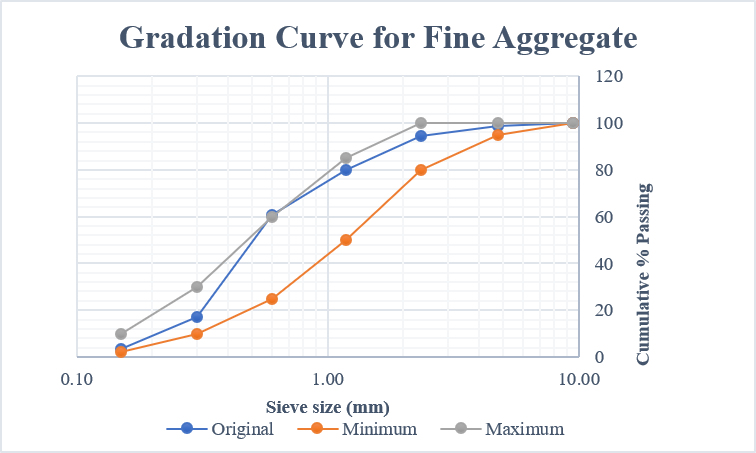

Source of sample: Lawrencepur sand

Fine Aggregate

| Sieve No. | Sieve Size (mm) | Weight Retained

(gm) |

% weight retained

|

Cumulative %age retained | % Passing | Min.% passing | Max. % passing |

| 3/8” | 9.50 | 0 | 0 | 0 | 100 | 100 | 100 |

| #4 | 4.75 | 12 | 1.2 | 1.2 | 98.8 | 95 | 100 |

| #8 | 2.36 | 44 | 4.4 | 5.6 | 94.4 | 80 | 100 |

| #16 | 1.18 | 144 | 14.4 | 20 | 80 | 50 | 85 |

| #30 | 0.6 | 249 | 24.9 | 44.9 | 55.1 | 25 | 60 |

| #50 | 0.3 | 370 | 37 | 81.9 | 18.1 | 10 | 30 |

| #100 | 0.15 | 148 | 14.8 | 96.7 | 3.3 | 2 | 10 |

| pan | 33 | 3.3 | 100 |

Results:

Cumulative % retained on sieve # 100 = 1.2+5.6+20+44.9+81.9+96.7=250.3

Observations & Calculations

Source of sample: Sargodha crush

Coarse Aggregate

| Sieve No. | Sieve size (mm) | Weight Retained | % weight Retained | Cumulative% retained | % Passing | Min % passing | Max % passing |

| 3″ | 75 | 0 | 0 | 0 | 100 | 100 | 100 |

| 1.5″ | 37.5 | 0 | 0 | 0 | 100 | 95 | 100 |

| 3/4″ | 19 | 35 | 0.7 | 0.7 | 99.3 | 35 | 70 |

| 3/8″ | 9.5 | 4198 | 83.96 | 84.66 | 15.34 | 10 | 30 |

| #4 | 4.75 | 757 | 15.14 | 99.8 | 0.2 | 0 | 5 |

| #8 | 2.36 | 10 | 0.2 | 100 | 0 | 0 | 0 |

Results:

Cumulative % retained on sieve # 4 = 0+0+0.7+84.66+99.8= 185.16

![]()

Comments:

- The experiment has been performed successfully and the fineness modulus of different samples have been calculated which are shown in tabular form below.

| Name of Sample | Fineness Modulus |

| Lawrencepur sand | 2.503 |

| Sargodha Crush | 1.851 |

· Categorization of fineness of sand using fineness modulus

| Fineness modulus | Sand fineness |

| <1 | very fine |

| 1 to 2 | fine |

| 2 to 2.9 | medium |

| 2.9 to 3.5 | coarse |

| > 3.5 | very coarse |

- So, the Lawrencepur sand lies in the category of medium coarse sand

- The value of fineness modulus is between 2.5 and 3.1, hence it is good fine aggregate

- The graphs of the gradation curve are intersecting because the material is not well graded.