Job # 6

To perform impact test on different steel samples

Purpose:

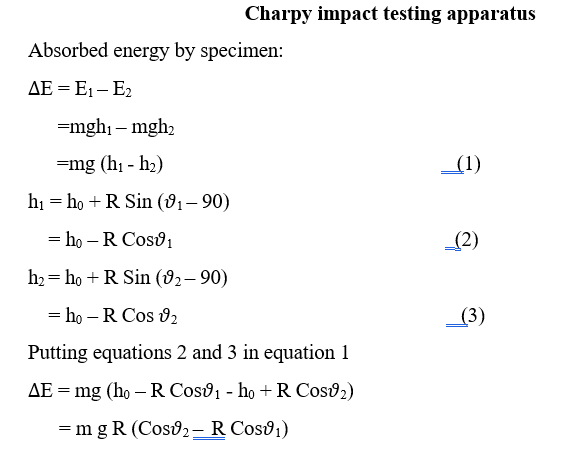

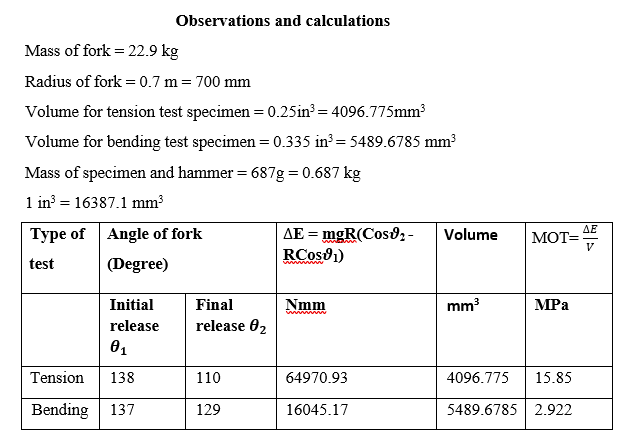

To determine the modulus of toughness of steel in tension and in bending.

Apparatus:

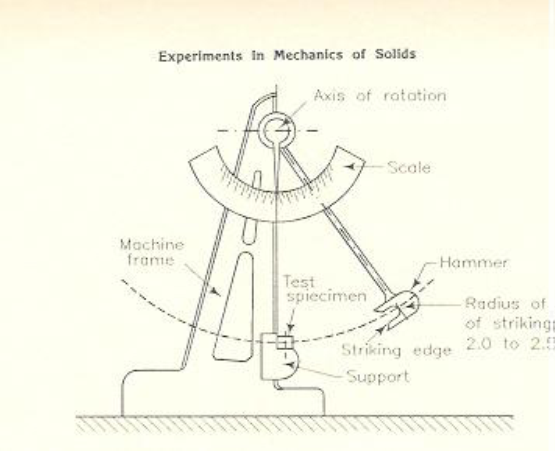

- Charpy impact testing machine

- Steel samples, circular rod for tension test and specimen with square cross section for bending test

Related theory:

- Toughness: The ability of material to absorb energy in plastic range as load is increased from 0 to failure.

- Modulus of toughness: It is the amount of work done on a unit volume of material as a simple tensile force is increased from 0 to failure.

- Types of loads:

- Static load: Loads which do not change their magnitude, direction and position. e.g. self weight of anything.

- Dynamic load: The loads which change their magnitude, direction and position. e.g traffic load on roads, bridges.

- Impact load: The sudden application of the significant magnitude of load in a short interval of time. e.g. earth quack produces impact load.

Procedure:

- Measure the dimensions of a specimen. Also, measure the dimensions of the fork i.e its radius and mass.

- Raise the hammer and note down initial reading from the dial, which will be energy to be used to fracture the specimen.

- Place the specimen for test and see that it is placed center with respect to hammer. Check the position of notch.

- Release the hammer and note the final reading. Difference between the initial and final reading will give the actual energy required to fracture the Specimen.

- Repeat the test for specimens of other materials.

- Compute the energy of rupture of each specimen.