Job 3

To perform direct shear test on a plane steel bar and punching shear test on steel plate

Objective:

To determine the shear strength of steel samples

Apparatus:

- 10 ton Buckton UTM

- Shear jigs

- Vernier calipers

- Steel bar

- Steel plate

Related theory:

- Shear force (V) :

A force which tends to slide one part of a section against the adjacent is known as shear force.

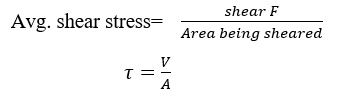

- Shear stress / tangential stress (

):

It is the intensity of the internal forces on a plane area when the forces are acting parallel to the section.

Note: A uniform shearing stress will exist when the resultant shear force passes through the centroid of the cross section being sheared.

- Types of shear stress:

- Direct shear:

If the force applied is parallel to the area being sheared, then it is direct shear.

Following are the types of direct shear.

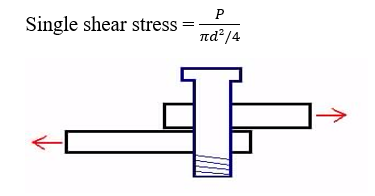

- Single shear:

Shear stress induced due to a force causing single area of cross section to be sheared is called single shear.

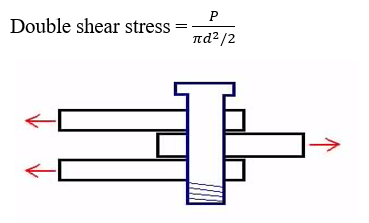

- Double shear:

Shear stress induced due to a force causing double area of cross section to be sheared.

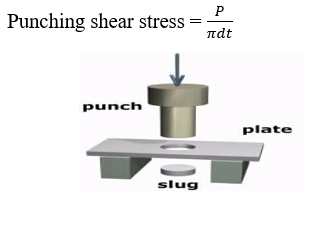

- Punching shear:

Shear stress induced due to a force causing one part to be punched into the other.

Area being sheared is again parallel to applied load.

- Induced shear:

Shearing stress induced due to a force which acts at an angle to the area being sheared.

Procedure:

- Insert the specimen in position and grip one end of the attachment in the upper portion and one end in the lower position

- Switch on the UTM

- Bring the drag indicator in contact with the main indicator.

- Select the suitable range of loads and space the corresponding weight in the pendulum and balance it if necessary with the help of small balancing weights

- Operate (push) the button for driving the motor to drive the pump.

- Gradually move the head control ever in left hand direction till the specimen shears.

- Note down the load at which the specimen shears.

- Stop the machine and remove the specimen.

Repeat the experiment with other specimens.

Observations and calculations

For direct shear test on plane steel bar:

| Shear load | Diameter (d) | Avg. (d) | Area=

|

Shear strength=

|

||||

| (mm) | ||||||||

| Tons | N | D1 | D2 | D3 | mm | mm2 | MPa | Psi |

| 1.132 | 10074.8 | 6.50 | 6.55 | 6.70 | 6.58 | 34 | 296.3 | 42975 |

For punching shear test on a steel plate:

| Shear load | Diameter of jigs (d) | Avg. (d) | Plate thickness

(t) |

Shear area

) |

Shear strength=

|

|||

| (mm) | ||||||||

| Tons | N | Upper jig | Lower jig | mm | mm | mm2 | MPa | Psi |

| 2.586 | 23015.4 | 14.90 | 15.20 | 15.05 | 2.10 | 99.29 | 231.79 | 33618.9 |