Job 5:

To Measure Surface Frictional Properties Using British Pendulum Skid Resistance Tester

Code: ASTM E 303- 93

SCOPE & SIGNIFICANCE:

This test method covers the procedure for measuring surface frictional properties using the British Pendulum Skid Resistance Tester.

- The British Pendulum Tester is a dynamic pendulum impact-type tester used to measure the energy loss when a rubber slider edge is propelled over a test surface.

- This test method provides a measure of a frictional property, micro texture, of surfaces, either in the field or in the laboratory.

- This test method may be used to determine the relative effects of various polishing processes on materials or material combinations.

- The values measured in accordance with this method do not necessarily agree or directly correlate with those obtained utilizing other methods of determining friction properties or skid resistance.

- The values measured, BPN = British Pendulum (Tester) Number for flat surfaces, represent the frictional properties obtained with the apparatus.

- Road pavements are designed to provide reasonably high coefficient of friction but with the movement of traffic, the aggregates in the wearing coarse of the road get polished resulting in reduction of the frictional or skid resistance of the road.

- British Pendulum Tester is used to measure the frictional resistance of road at sections which appear to be potentially slippery and unsafe against skidding.

- Friction between vehicle and road surface plays a vital role in determining the maximum operating speed and the distance required in safely stopping the vehicles. Braking distance is particularly important at crossings, road signals, school intersections and turns, etc.

- Higher the skid-resistance results, better is the road surface but a high value of skid-resistance also increases the chances of severe injuries.

- More the texture depth, better is the road surface but a high value of texture depth also increases the chances of severe injuries.

RELATEDTHEORY:

SKIDDING:

In skidding, the distance traveled by wheel on the road is more than the circumferential movement.

OR

If the wheels of the vehicle are not rotating but the vehicle keeps moving forward, then skidding is said to occur.

When brakes are applied, wheels get locked and still if the vehicle moves ahead, longitudinal skidding is said to occur. Skid is a term which is very much connected with friction.

SLIPPING:

In slipping, the distance traveled by wheel on the road is less than the circumferential movement.

OR

If the wheels of the vehicle are rotating but the vehicle is not moving forward, then slipping is said to occur.

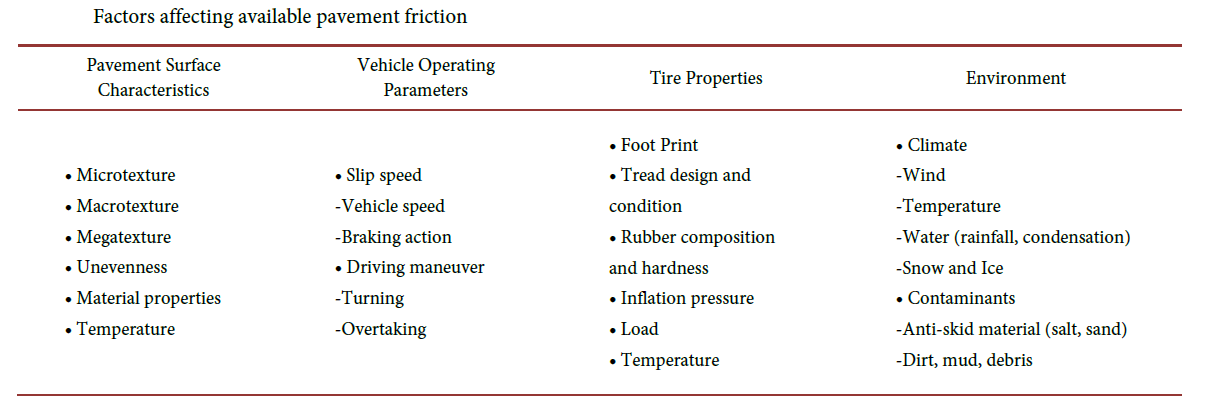

FACTORS AFFECTING SKIDDING RESISTANCE:

- Condition of Tires – Vehicles having smooth tires would have slightly low skidding resistance.

- Effect of Road Temperature – Skidding resistance of wet roads is higher in winter than in summer. Skidding resistance of roads is at its lowest between April and September. So, roads with satisfactory values in winter may prove slippery during summer.

- Effect of Water – Skidding resistance is lower on wet than on dry pavements.

- Type of aggregate – Sand stones and granites are more resistant to polishing action than limestone.

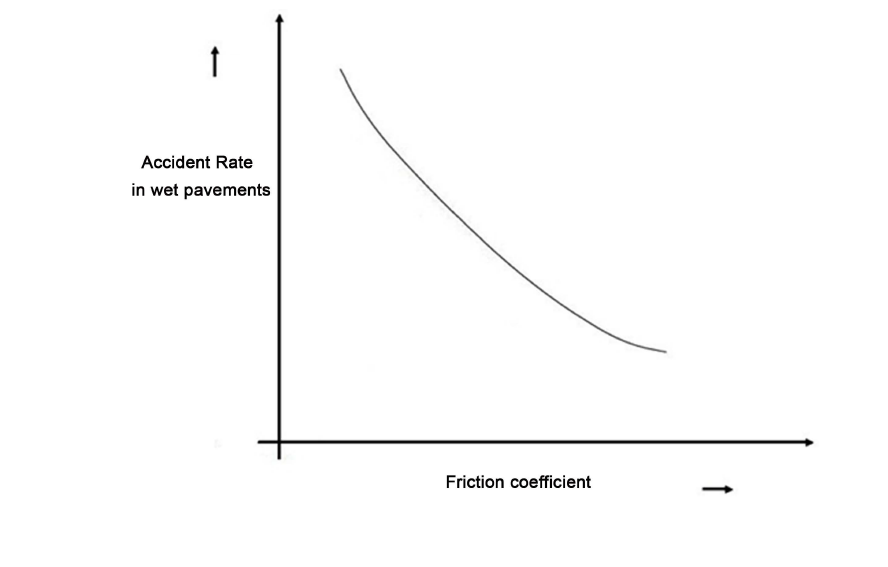

Relationship between crash rates in wet weather conditions and pavement surface friction:

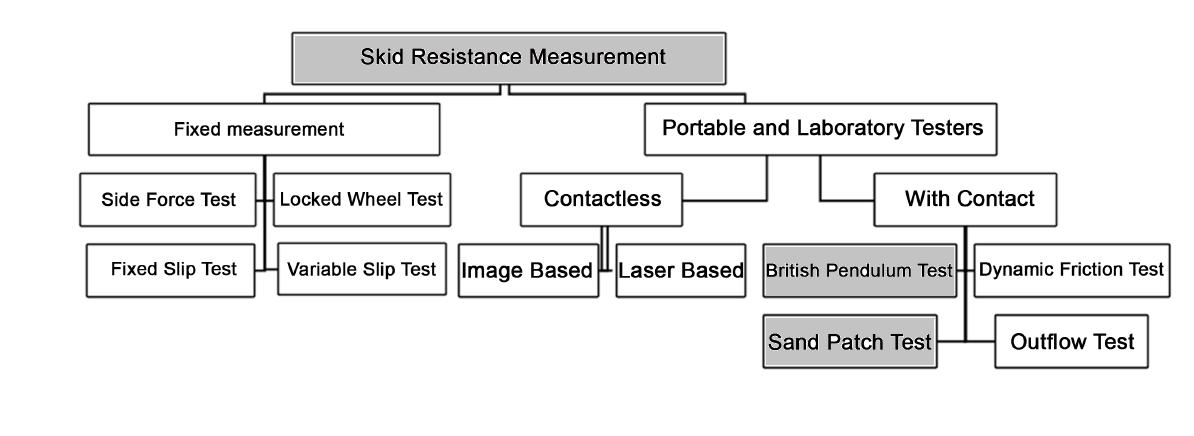

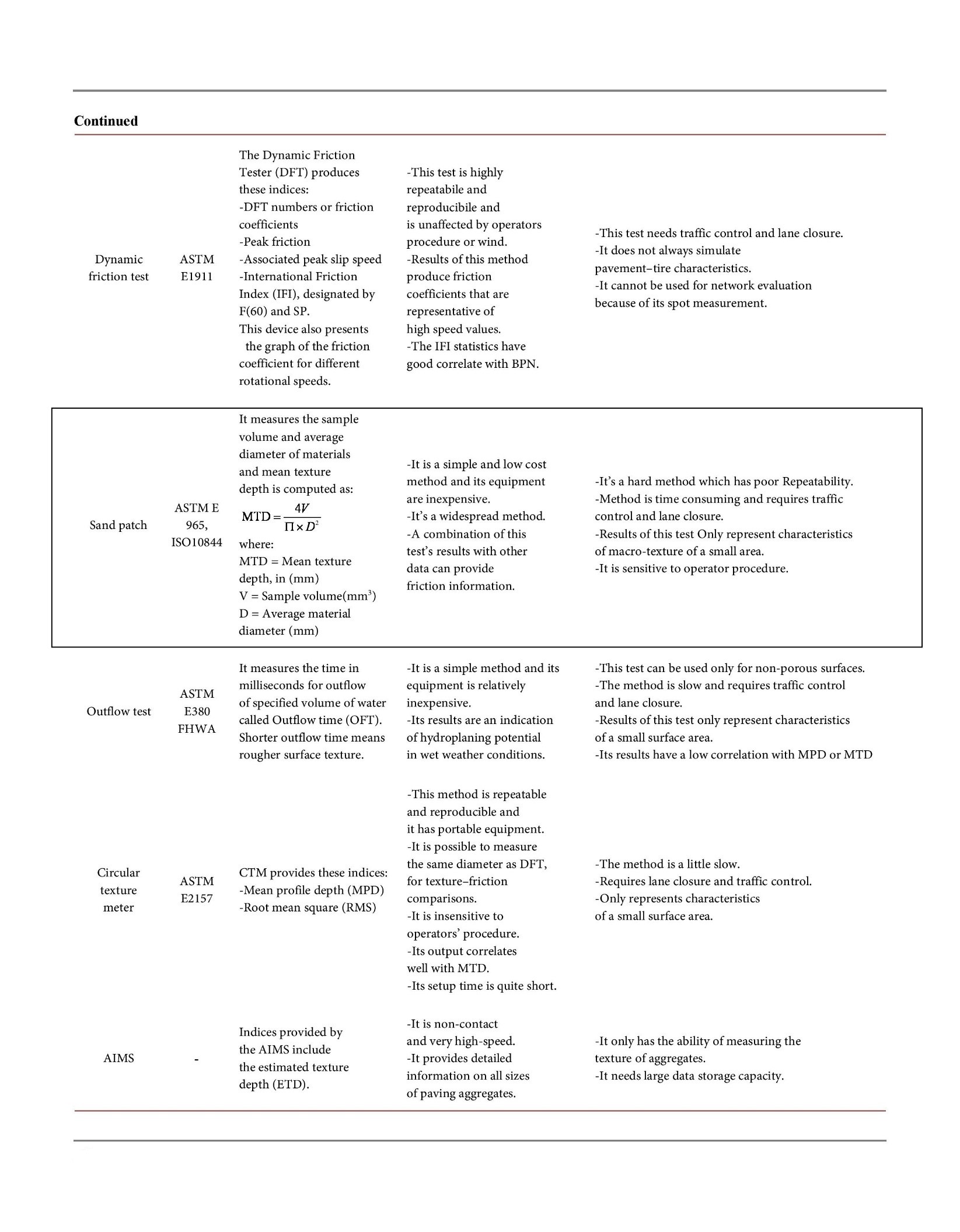

Classification of skid resistance measurement method:

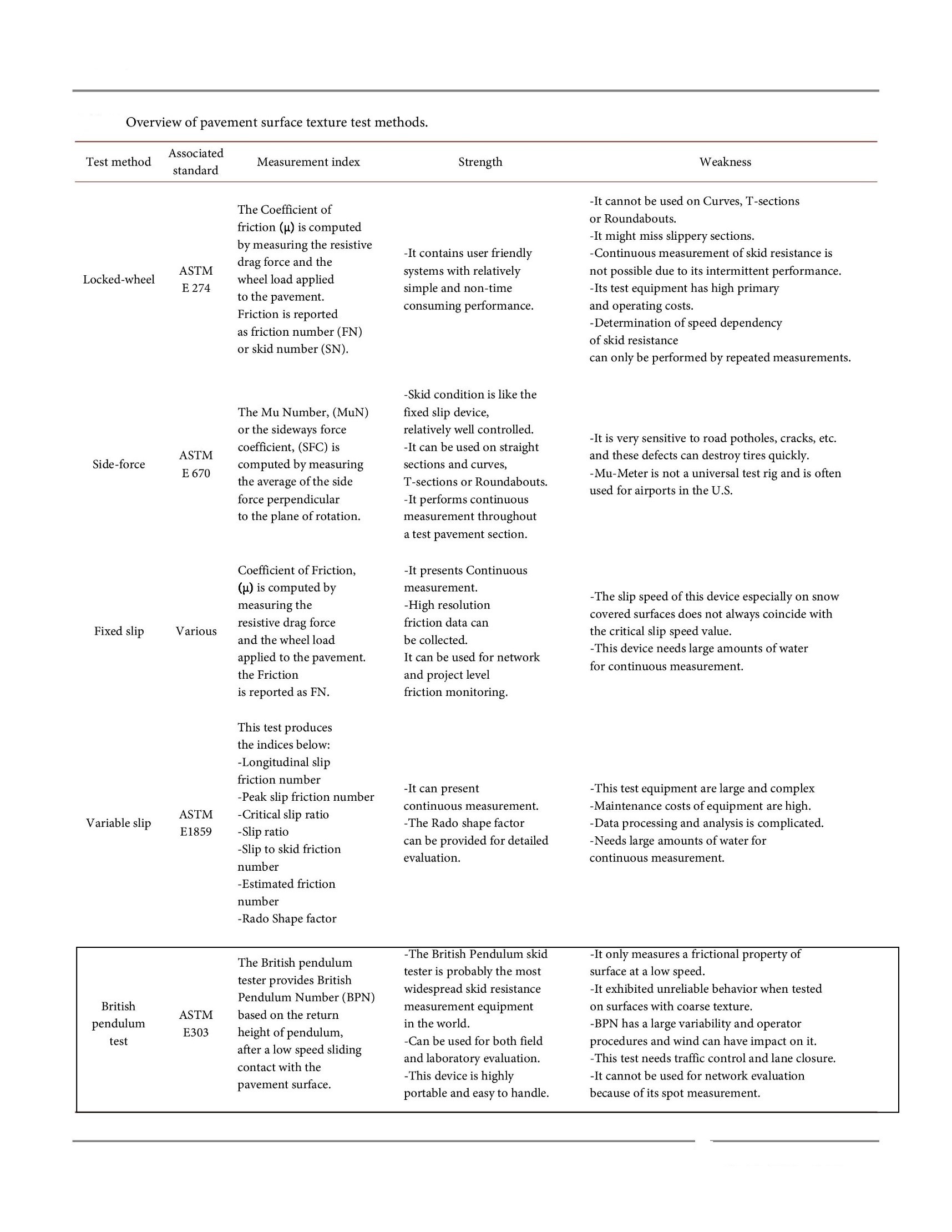

OVERVIEW OF PAVEMENT SURFACE TEXTURE TEST METHODS:

Source: “Pavement friction and skid resistance measurement methods, Open journal of civil engineering”

APPARATUS:

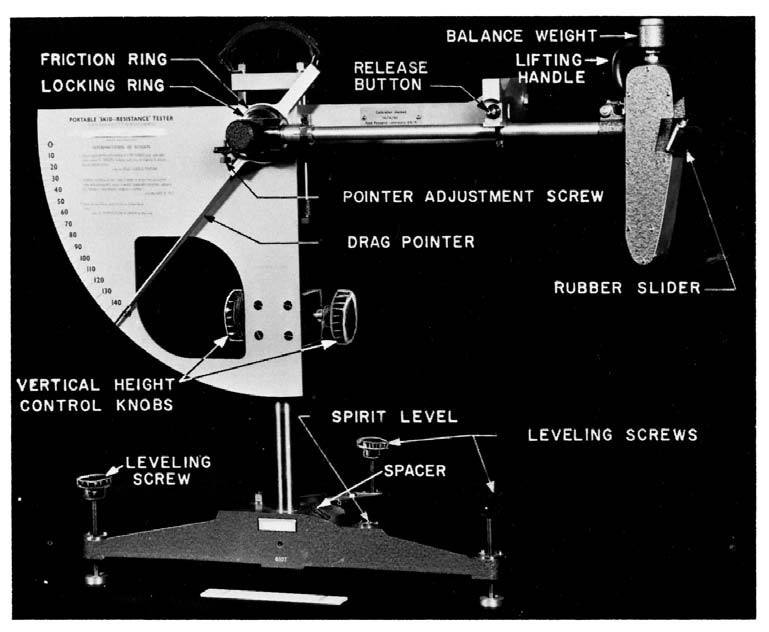

British Pendulum Tester (Fig. 1)

The pendulum with slider and slider mount shall weigh 1500 ± 30 g.

The distance of the center of gravity of the pendulum from the center of oscillation shall be 411 ± 5 mm (16.2 ± 0.2 in.).

The tester shall be capable of vertical adjustment to provide a slider contact path of 125 ± 1.6 mm (415⁄16 + 1⁄16 in.) for tests on flat surfaces, and 76 to 78 mm (3 ± 1⁄16 in.) for tests on polishing-wheel specimens.

Fig: 1 British Pendulum Tester

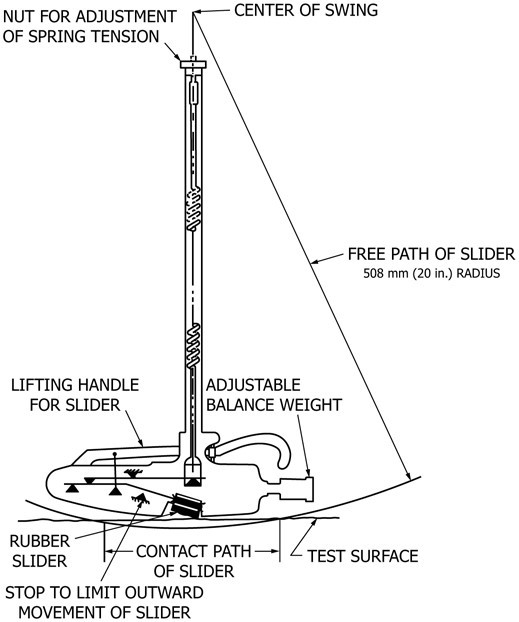

The spring and lever arrangement shown in Fig. 2 shall give an average normal slider load between the 76-mm (3-in.) wide slider and test surface of 2500 ± 100 g as measured by the method prescribed in the annex.

Slider—The slider assembly shall consist of an aluminum backing plate to which is bonded a 6 by 25 by 76-mm (1⁄4 by 1 by 3-in.) rubber strip for testing flat surfaces or a 6 by 25 by 32 mm (1⁄4 by 1 by 11⁄4-in.) rubber strip for testing curved polishing-wheel specimens. The rubber compound shall be natural rubber meeting the requirements of the Road Research Laboratory or synthetic rubber

New sliders shall be conditioned prior to use by making ten swings on No. 60 grade silicon carbide cloth or equivalent under dry conditions.

Fig: 2 Schematic Drawing of Spring and Lever Arrangement

Parts

- Slider – slider assembly consists of an aluminum backing plate to which a rubber strip 3’’ x 1’’ x ¼’’ is bonded.

- Leveling screws

- Scale

- Drag pointer

- Locking and control knobs and

- Frictional rings

Accessories

- Contact path gauge – shall consist of a thin ruler suitably marked for measuring contact path length between (4 7/8’’ and 5’’).

- Water container

- Surface thermometer and

- Brush

PREPARATION OF APPARATUS:

Leveling – Level the instrument accurately by turning leveling screws until the bubble is centered in the spirit level.

Zero adjustment – Raise pendulum mechanism by loosening locking knob (directly behind pendulum pivot) and turn either of pair of head movement knobs at center of tester to allow slider to swing free of test surface. Tighten locking knob firmly. Place pendulum in release position and rotate the drag pointer counter clockwise until it comes to rest against adjustment screw on pendulum arm. Release pendulum and note pointer reading. If reading is not zero, loosen locking ring and rotate friction ring on bearing spindle slightly and lock again. Repeat test and adjust friction ring until the pendulum swing carries pointer to zero.

Slide length adjustment – With pendulum hanging free, place spacer under adjusting screw of lifting handle. Lower pendulum so edge of slider just touches surface. Lock pendulum head firmly, raise lifting handle, and remove spacer.

Raise slider by lifting handle, move pendulum to right lower slider, and allow pendulum to move slowly to left until edge of slider touches surface. Place gage beside slider and parallel to direction of swing to verify length of contact path. Raise slider, using lifting handle, and move pendulum to left, then slowly lower until slider edge again comes to rest on surface. If the length of the contact path is not between 124 and 127 mm (47⁄8 and 5.0 in.) on flat test specimens or between 75 and 78 mm (215⁄16 and 31⁄16 in.) on curved polishing-wheel specimens, measured from trailing edge to trailing edge of the rubber slide, adjust by raising or lowering instrument with the front leveling screws. Readjust level of instrument if necessary. Place pendulum in release position and rotate the drag pointer counter-clockwise until it comes to rest against adjustment screw on pendulum arm.

Place pendulum in release position and rotate drag pointer counter clockwise until it comes to original position. Inspect the road and choose the section to be tested. Set the apparatus so that the slider swings in the direction of traffic.

PROCEDURE:

- The pendulum slider is positioned to barely come in contact with the test surface prior to conducting the test. The pendulum is raised to a locked position, then released, thus allowing the slider to make contact with the test surface.

- A drag pointer indicates the British Pendulum (Tester) Number. The greater the friction between the slider and the test surface, the more the swing is retarded, and the larger the BPN reading.

- Apply sufficient water to cover the test area thoroughly. Execute one swing but don’t record reading.

- Without delay, make four more swings, rewetting the test area each time and record the results.

- The readings should not differ by more than 3 units.

- Report the individual values as B.P.N. also note down the age, condition, texture and location of test area.

MEASUREMENT OF TEXTURE DEPTH:

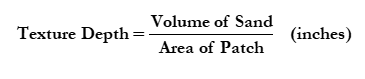

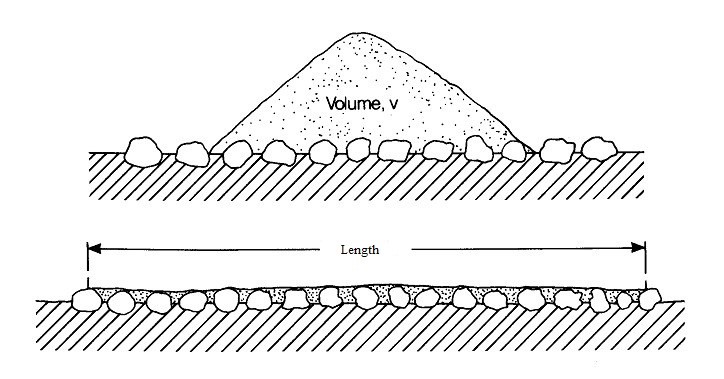

It is also necessary to record the surface texture of the road surface tested. This is measured by Sand Patch Method.

A known volume of fine sand of uniform particle size is poured on the road and spread to form a patch of a regular shape so that its area can be measured. Sand should be spread in such a manner that all “valleys” are filled to level of “peaks”. Then the texture depth can be computed by using the formula;

| ROAD SURFACE TEXTURE | TEXTURE DEPTH |

| Coarse/Open Texture | ≥ 0.02” |

| Medium Texture | 0.02” – 0.01” |

| Fine Texture | ≤ 0.01” |

SUGGESTED VALUES OF SKID-RESISTANCE:

| CATEGORY | TYPE OF SITE | ‘SKID RESISTANCE’ ON WET SURFACE | STANDARD OF SKIDDING RESISTANCE REPRESENTED |

| A | Most difficult sites such as;

i)- Roundabouts ii)- Bends with radius less than 500 ft on derestricted roads. iii)- Gradients, 1 in 20 or steeper, of length greater than 100 yd. iv)- Approach to traffic lights on derestricted roads. |

Above 65 | ‘Good’: fulfilling the requirements even of fast traffic, and making it most unlikely that the road will be the scene of repeated accidents. |

| B* | General requirements, i.e. roads and conditions not covered by categories A & C. | Above 55 | ‘Generally Satisfactory’: meeting all but the most difficult conditions encountered on the roads. |

| C* | Easy sites, e.g. straight roads, with easy gradients and curves, without junctions, and free from any features, such as mixed traffic, especially liable to create conditions of emergency. | Above 45 | ‘Satisfactory only in favorable circumstances.’ |

| D | All sites | Below 45 | ‘Potentially Slippery’ |

| * On smooth-looking or fine-textured roads in these categories, vehicles having smooth tyres may not find skid-resistance adequate. For such road accident studies should also be made to ensure that there are no indications of difficulties due to skidding under wet conditions. | |||

OBSERVATIONS & CALCULATIONS

Computation of Texture Depth

| Group | Dimensions of Patch | Area | Volume of Sand | Texture Depth | |

| (cm x cm) | (cm2) | (ml = cm3) | (cm) | (inches) | |

| 2 | 19.5 x 29.5 | 575.25 | 50 | 0.0869 | 0.0342 |

British Pendulum Number

| Group | Date | Distance from | Distance

(cm) |

Surface Texture

(in) |

Skid-Resistance

(BPN) |

Mean

(BPN) |

| 2 | 9th October 2017 | Staff colony maintenance cell | 15 | 0.0342 | 68, 70,

68, 67 |

68 |

RESULTS & COMMENTS:

- The road surface texture is coarser/ open texture because texture depth value is 0.03” which is greater than 0.02”.

- The skid-resistance value indicates that, the road surface where we performed the test is very Good falls in A category (i.e above 65) fulfilling the skid-resistance requirements even of fast traffic, and making it most unlikely that the road will be the scene of repeated accidents.