Job 8

SPECIFIC GRAVITY TEST ON BITUMINOUS MATERIALS

Code: ASTM: D 70-09

SCOPE &SIGNIFICANCE:

This test method covers the determination of the relative density and density of semi-solid bituminous materials, asphalt cements, and soft tar pitches by use of a pycnometer.

- Specific gravity of a bitumen binder is a fundamental property frequently required as an aid in classing binders for use in paving jobs.

- Bitumen weights sometimes have to be converted into volumes for asphalt concrete mix design calculations for which a knowledge of specific gravity is essential.

- Specific gravity is also used in identifying the source of bitumen binder.

- Bitumen binder has specific gravity in the range of 0.97 to 1.02.

- In case bitumen contains mineral impurities the specific gravity will be higher. Thus, it is possible for a quantitative extraction of mineral impurity in bitumen.

RELATEDTHEORY:

SPECIFIC GRAVITY

The specific gravity of semi-solid bituminous material, asphalt cements, and soft tar pitches shall be expressed as the ratio of the mass of a given volume of the material at 25 °C to that of an equal volume of water at the same temperature.

SOURCES OF BITUMEN:

Bitumen is generally obtained from the following three sources;

- Naturally occurring (in West Indies).

- Extracted from Limestone and Sandstone (procedure adopted in USA).

- From Oil Refineries (this is the major source of bitumen in Pakistan).

GRADES OF BITUMEN:

Bitumen is usually characterized in the following three types of grades;

- Viscosity grades

- Penetration grades

- Density grades

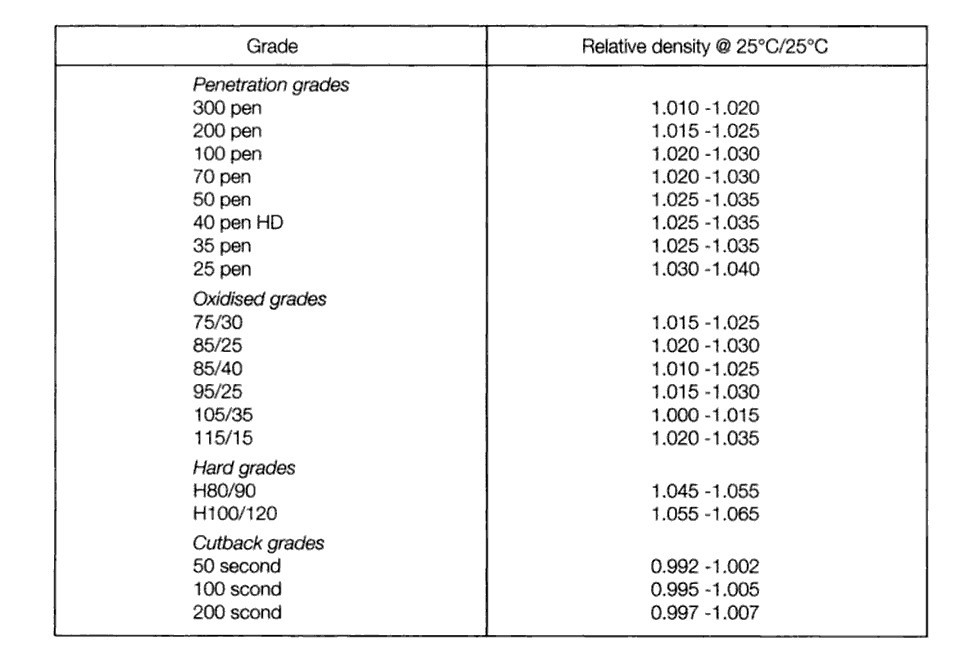

GRADES ACCORDING TO RELATIVE DENSITY OF BITUMEN:

Source: Shell bitumen industry handbook

PENETRATION GRADE BITUMEN:

Source: Construction Materials for Civil Engineers by Errol Van

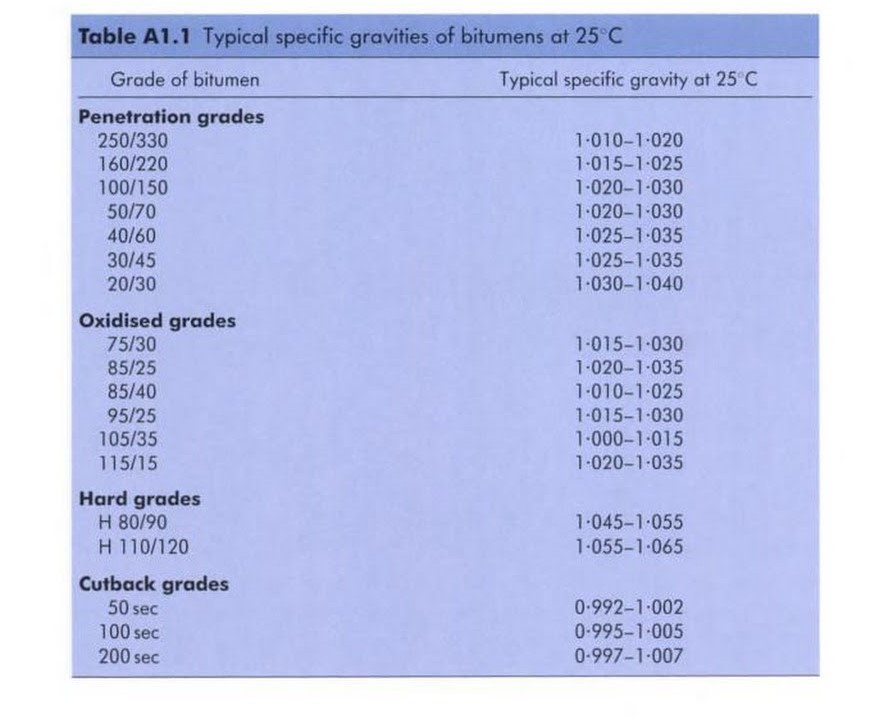

GRADES ACCORDING TO RELATIVE DENSITY OF BITUMEN:

Source: Shell bitumen industry handbook

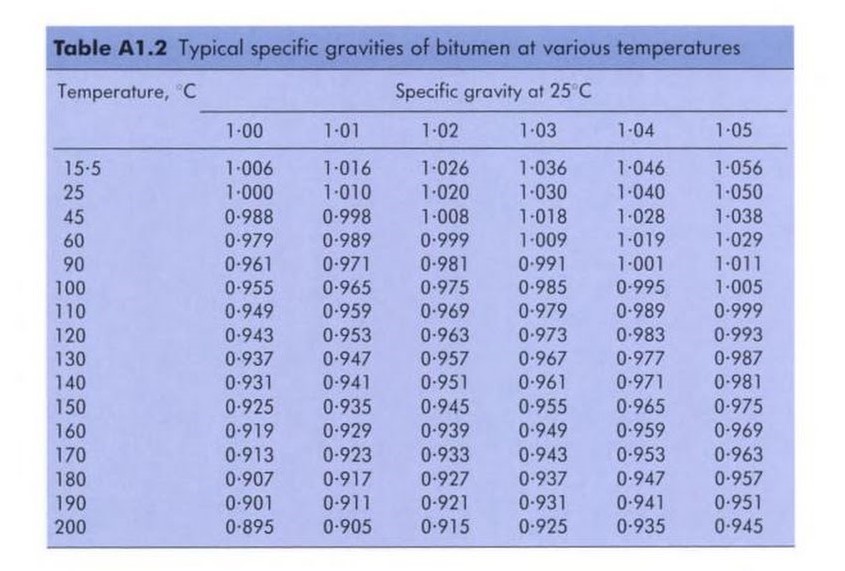

RELATIONSHIP BETWEEN TEMPERATURE AND SPECIFIC GRAVITY OF BITUMEN:

Source: Shell bitumen industry handbook

APPARATUS:

- Pycnometer

Glass, consisting of a cylindrical or conical vessel carefully ground to receive an accurately fitting glass stopper 22 to 26 mm in diameter. The stopper shall be provided with a hole 1.0 to 2.0 mm in diameter, centrally located in reference to the vertical axis. The top surface of the stopper shall be substantially plane and have no chips, and the lower surface shall be concave to allow all air to escape through the bore. The height of the concave section shall be 4.0 to 18.0 mm at the center. The stoppered pycnometer shall have a capacity of 24 to 30 mL and shall weigh not more than 40 g.

- Water Bath

Constant-temperature, capable of maintaining the temperature within 0.1°C of the test temperature.

- Thermometric device

Calibrated liquid in glass, total immersion type, of suitable range with graduations at least every 0.1°C and a maximum scale error of 0.1°C. Thermometer commonly used is ASTM 63°C. Any other thermometric device of equal accuracy may be used.

- Balance

Capable of making the required measurements to an accuracy of at least 0.001g.

- Beaker

600 mL or larger Griffin low-form beaker.

- Water

Freshly boiled and cooled distilled or deionized water.

PROCEDURE

Calibration of Pycnometer:

- Thoroughly clean, dry, and weigh the pycnometer to the nearest 0.001 g. Designate this mass as A.

- Fill the pycnometer with freshly boiled distilled or deionized water, placing the stopper loosely in the pycnometer. Place the pycnometer in the beaker and press the stopper firmly in place. Return the beaker to the water bath if previously removed.

- Allow the pycnometer to remain in the water for a period of not less than 30 min. Remove the pycnometer, immediately dry the top of the stopper with one stroke of a dry towel, then quickly dry the remaining outside area of the pycnometer and weigh to the nearest 0.001 g. Designate the mass of the pycnometer plus water as B.

Preparation of Sample:

- Heat the sample with care, stirring to prevent local overheating, until the sample has become sufficiently fluid to pour.

- In no case should the temperature be raised to more than 55°C above the expected softening point for tar, or to more than 110°C above the expected softening point for asphalt.

- Do not heat for more than 60 min, and avoid incorporating air bubbles into the sample.

- Pour enough sample into the clean, dry, warmed pycnometer to fill it about three fourths of its capacity. Take precautions to keep the material from touching the sides of the pycnometer above the final level and prevent the inclusion of air bubbles. Allow the pycnometer and its contents to cool to ambient temperature for a period of not less than 40 min and weigh with the stopper to the nearest 0.001 g. Designate the mass of the pycnometer plus sample as C.

- Remove the beaker from the water bath if necessary. Fill the pycnometer containing the asphalt with freshly boiled distilled or deionized water, placing the stopper loosely in the pycnometer. Do not allow any air bubbles to remain in the pycnometer. Place the pycnometer in the beaker and press the stopper firmly in place. Return the beaker to the water bath if previously removed.

- Allow the pycnometer to remain in the water bath for a period of not less than 30 min. Remove the pycnometer from the bath. Dry and weigh using the same technique and timing as that employed previously. Designate this mass of pycnometer plus sample plus water as D.

- Calculate specific gravity to nearest 0.001

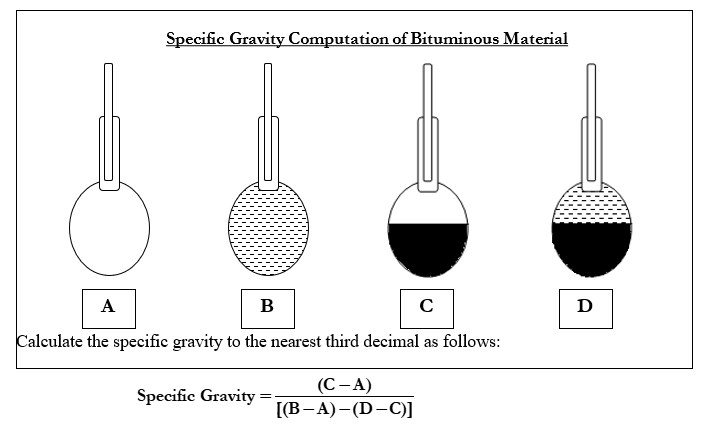

CALCULATIONS:

Where,

A = mass of Pycnometer + stopper

B = mass of Pycnometer filled with water

C = mass of Pycnometer partially filled with asphalt

D = mass of Pycnometer + asphalt + water

PRECAUTIONS:

- Only freshly boiled and cooled distilled water will be used.

- At no time of weighing, the temperature of apparatus be allowed to exceed the specific temperature of test.

- All the air bubbles must be eliminated.

- Do not heat the specimen directly as this may result in localized heating causing bitumen to ignite.

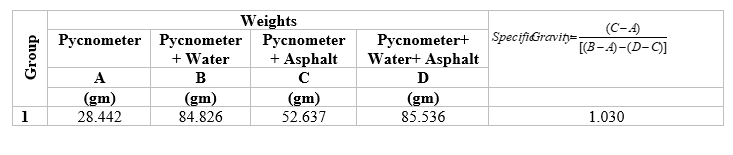

OBSERVATIONS & CALCULATIONS

RESULTS & COMMENTS:

Specific gravity = 1.030

Penetration grade of bitumen = 100/150

- The permissible range for specific gravity of Bitumen is 0.97-1.02. The Specific gravity of sample is greater than permissible limit of 1.02.

- The results also confirm that, sample has more mineral impurities in it as its specific gravity is higher.

- The specific gravity can be measured using either pycnometer or preparing a cube specimen of bitumen in semi solid or solid state

- The asphalt can be rinsed with carbon disulphide, benzol, trilene (trichloro ethylene) etc.

METHOD 2:

BALANCE METHOD FOR DETERMINATION OF SPECIFIC GRAVITY OF BITUMEN:

This balance method of test is intended for the determination of the specific gravity of all bituminous materials sufficiently solid to be handled in fragments.

APPARATUS:

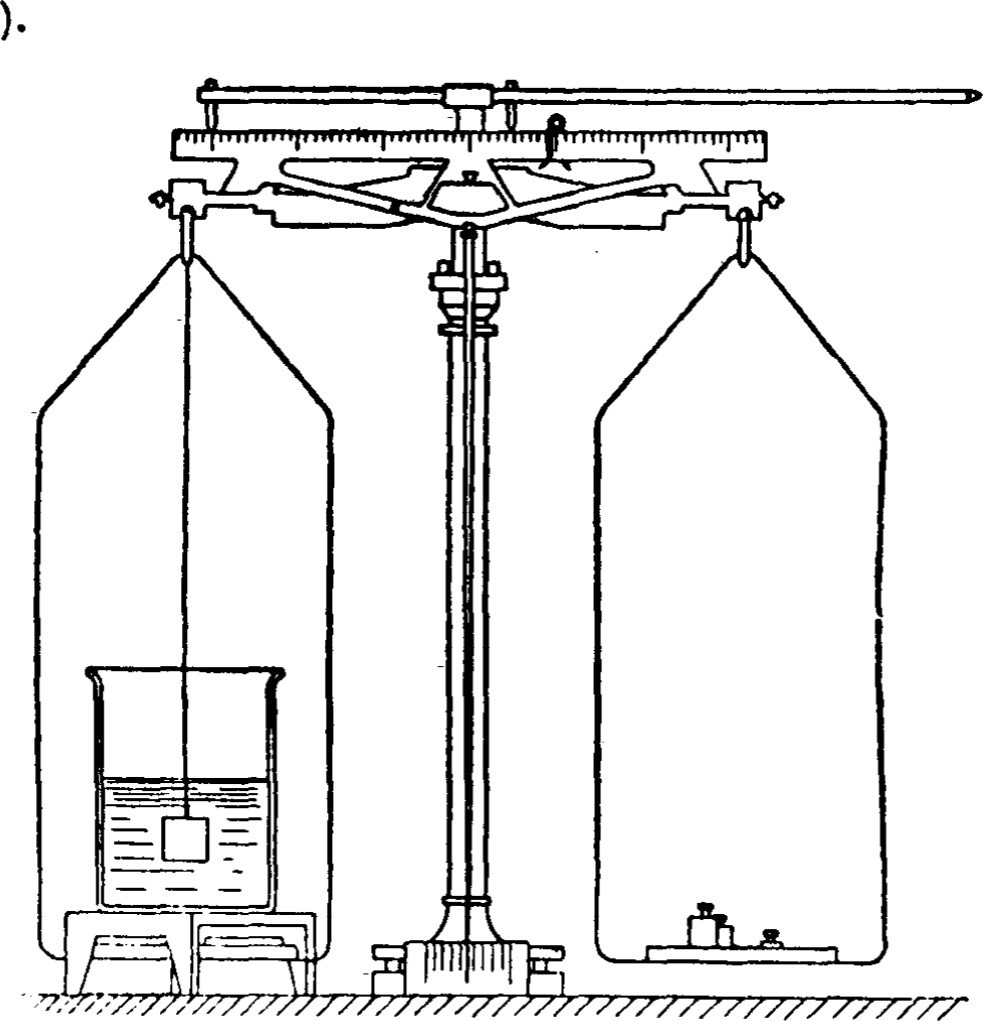

- Balance Analytical

- Thermometer

- Balance Straddle —A pan straddle of convenient to support a beaker and permit determination of the weight of the specimen in water

Analytical Balance Equipped with Pan Straddle

- Thread— A length of fine, waxed, silk thread.

- Brass Moulds — cubical, measuring approximately 20 mm on each edge.

TEST SPECIMEN:

The test specimen shall be a cube of the material measuring approximately 20 mm on each edge. Prepare the specimen by melting a small sample of the material by gentle application of heat, taking care to prevent loss by evaporation, and pouring the material when sufficiently fluid into a 20 mm brass cubical mould that has been treated with a 1 : 1 mixture of glycerine and dextrin and placed on a brass plate previously so treated. Take precautions to prevent the inclusion of air bubbles. The hot material should be slightly more than that required to fill the mould, and when cool, the excess may be cut off with a hot spatula. Remove the specimen from the mould when cooled to room temperature.

PROCEDURE:

Tare the balance first- with a piece of fine waxed silk thread sufficiently long to reach from the hook on one of the pan supports to the rest. Attach the specimen to the thread, so as to be suspended about 25 mm above the straddle from the hook on the pan support, and weigh to the nearest 0.1 mg. Weigh the specimen, still suspended by thread, and completely immersed in freshly boiled and cooled distilled water at 25OC, to the nearest 0.1mg, adhering air bubbles being first removed with a fine wire.

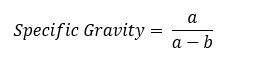

CALCULATIONS:

Calculate the specific gravity of the material as follows:

Where;

a = mass of the dry specimen, and

b = mass of the specimen when immersed in distilled water.

Source: Indian Standards