Job # 12:

Determination of tensile strength of concrete by Split cylinder test:

(ASTM C 496/C 496 M-04)

Significance:

- This test method is used for the determination of splitting tensile strength of cylindrical concrete specimen.

- Splitting tensile strength is generally greater than the direct tensile strength and lower than the flexural strength (modulus of rupture).

- Splitting tensile strength is used in the design of structural light weight concrete members to evaluate the shear resistance provided by concrete and to determine the development length of the reinforcement.

Apparatus:

- Denison Leeds, England Compression testing machine

- Testing Samples

- Bearing strips

Related theory:

Difficulties in measurement of tensile strength:

There are considerable experimental difficulties in determining the true tensile strength of concrete. In direct tension test following are the difficulties:

- When concrete is gripped by the machine it may be crushed due the large stress concentration at the grip.

- Concrete samples of different sizes and diameters show large variation in results.

- If there are some voids in sample the test may show very small strength.

- If there is some initial misalignment in fixing the sample the results are not accurate.

Indirect methods for the determination of tensile strength of concrete:

- Split cylinder test

- Double punch test

- Modulus of rupture test

Split cylinder test:

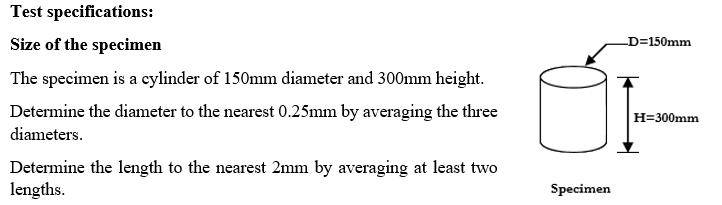

This test is performed by loading a standard 150mmФ x 300mm cylinder by a line load perpendicular to its longitudinal axis with cylinder placed horizontally on the testing machine platen.

The tensile strength can be defined as

T = 2P / (Π DL)

Where

P = Total value of line load registered by machine

D = Diameter of concrete cylinder

L = Cylinder height

Mean split cylinder strength is approximately 0.53√fc’

Rate of loading

The rate of loading should be such that a stress of 0.7 – 1.4 MPa/min is produced.

Procedure:

- This test method consists of applying a diametrical force along the length of a cylindrical concrete at a rate that is within a prescribed range until failure. This loading induces tensile stresses on the plane containing the applied load and relatively high compressive stresses in the area immediately around the applied load.

- Although we are applying a compressive load but due to Poisson’s effect, tension is produced and the specimen fails in tension. Tensile failure occurs rather than compressive failure because the areas of load application are in a state of triaxial compression, thereby allowing them to withstand much higher compressive stresses than would be indicated by a uniaxial compressive strength test result.

- Thin, plywood bearing strips are used to distribute the load applied along the length of the cylinder.

- The maximum load sustained by the specimen is divided by appropriate geometrical factors to obtain the splitting tensile strength.

Observations and Calculations

Age of cylinders = 28 days

Diameter of cylinder = 150 mm

Length of cylinder = 300 mm

1 Ton = 2240 lb

1 lb = 4.45 N

| Specimen no. | Length (L) | Diameter (D) | Maximum applied load (P) | Split tensile strength

T = 2P / (Π DL) |

|

| mm | mm | Ton | N | MPa | |

| 1 | 300 | 150 | 15.25 | 152012 | 2.15 |

| 2 | 300 | 150 | 15.75 | 156996 | 2.22 |

| Mean strength | 2.19 | ||||

Results:

Splitting tensile strength = 2.19 MPa

Comments:

- This is an indirect method of finding the tensile strength of concrete.

- the tensile strength obtained by this method is very close to the tensile strength obtained from double punch test which is about 2.73 MPa.

Sample during test: