Job 9

Determination of specific viscosity of liquid asphalts using Engler Viscometer:

ASTM DESIGNATION: D 1665-98

SCOPE & SIGNIFICANCE:

- This test method covers the determination of specific viscosity of tars and their fluid products. It does not determine absolute viscosity, but is an empirical flow test.

- This test method is useful in characterizing the consistency of tar and tar distillates by measuring their flow properties. It is applicable to materials that are readily liquid at temperatures up to 100°C.

- Viscosity in Engler’s degrees ≈ 1/4th of saybolt furol viscosity (seconds).

- The degree of fluidity at application temperature greatly influences the strength characteristics of resulting paving mixes. High or low fluidity at mixing and compaction has been observed to result in lower stability values.

- There is an optimum value of fluidity or viscosity for mixing and compaction for each aggregate grading of the mix and bitumen grade. At low Viscosity, thebinder simply lubricates the aggregate particles instead of providing a uniform film thickness for binding action. Similarly high viscosity also resists the compactive effort and the resulting mix will be heterogeneous in character exhibiting low stability values.

- Liquid asphalt is used to save large amount of energy required to melt/make workable the asphalt.

RELATED THEORY:

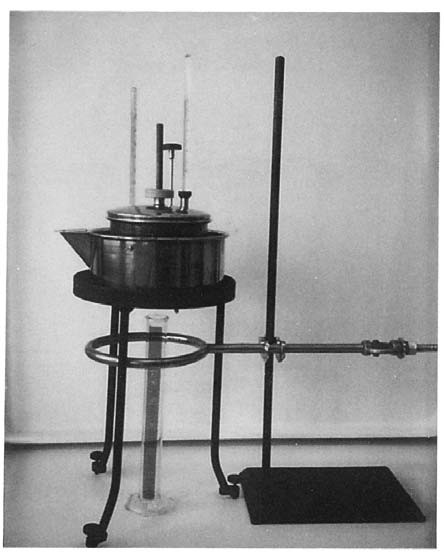

ENGLER SPECIFIC VISCOSITY:

The ratio obtained by dividing the time of flow, in s, of 50 mL of material using an Engler viscometer at a selected temperature by a factor representing the time of flow, in s, for an equal volume of water at 25°C.

The usual temperatures for determination of specific viscosity of tar materials are 25°C, 40°C, 50°C, and 100°C, and generally the temperature is so selected that the specific viscosity is not more than 45.

Engler’s viscometer which is efflux tube was developed in Germany. The method is basically empirical but it is possible to relate efflux time to absolute viscosity using charts/tables developed by Asphalt institute for this purpose.

Note: At a temperature more than 100°C, the water will boil. So, we cannot perform this test at a temperature more than 100°C.

SOURCES OF BITUMEN:

Bitumen is generally obtained from the following three sources;

- Naturally occurring (in West Indies).

- Extracted from Limestone and Sandstone (procedure adopted in USA).

- From Oil Refineries (this is the major source of bitumen in Pakistan).

GRADES OF BITUMEN:

Bitumen is usually characterized in the following three types of grades;

- Viscosity grades

- Penetration grades

- Density grades

Properties of BITUMEN:

- Bitumen is both flammable and combustible.

- Bitumen becomes volatile at high temperatures.

- The working temperature of the bitumen must be at least 100°C less than the flash point.

- By repeated heating and cooling of bitumen, more and more volatiles will be ejected and the properties of bitumen will be altered.

- Both bitumen and asphalt are different names of the same thing. It is called asphalt in America and bitumen in UK.

LIQUID ASPHALT:

It is the asphalt present in the liquid or semi-liquid state and having a flash point of about 60–70 °C. Liquid asphalt is in the liquid form due to the presence of mineral impurities.

Liquid asphalt is used to save large amount of energy required to melt/make workable the asphalt.

TYPES OF LIQUID ASPHALT:

Liquid asphalt is generally found in the following two forms;

- Cut back asphalt

- Emulsified asphalt

Cut back asphalt:

when volatile solvents are mixed with asphalt cement to make a liquid product, the mixture is called cutback asphalt.

Following are three types of cutback asphalt and the solvents used:

- Rapid curing (RC): Gasoline or naphtha

- Medium curing (MC): Kerosene

- Slow curing (SC): Road oils

Emulsified asphalt:

Emulsified asphalt is a mixture of asphalt cement, water and an emulsifying agent.

APPARATUS:

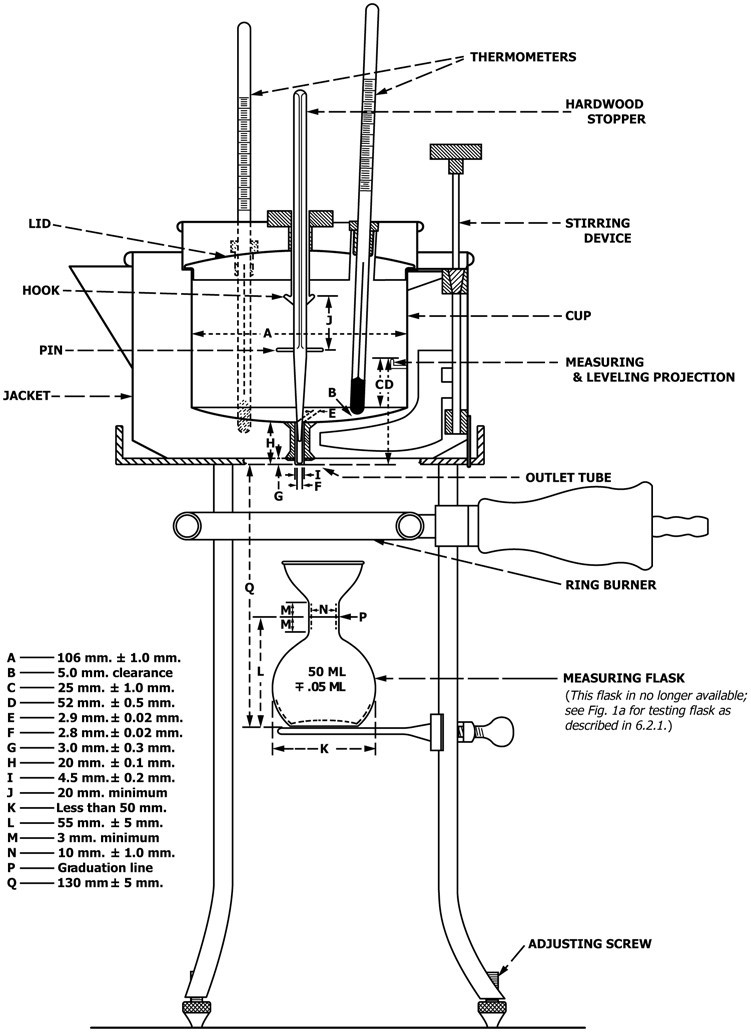

Engler Viscometer– as shown in figure, consist of the following parts:

- Cup— This is a gold-plated cylindrical brass vessel of 106.0 ± 1.0 mm, A, inside diameter, closed at the top by a double walled To the rounded bottom is attached a metal—encase tapered platinum efflux tube 20.0 ± 0.1 mm, H, long with an inside diameter of 2.90 ± 0.1 mm, E, at the top and 2.80 ± 0.02 mm, F, at the bottom. The efflux tube shall project through and extend 3.0 ± 0.2 mm, G, below a jacket that surrounds the cup and shall have a bottom outside diameter, including its surrounding metal, of 4.5 ± 0.2 mm, 1. Three metal measuring points, spaced equidistantly around the circumference of the cup, are fastened to the sides and extend inwardly approximately 7 mm, then turn up at a right angle and end in sharp points which are located 52.0 ± 0.5 mm, D, vertically above the lower end of the efflux tube and 25.0 ± 1.0 mm, C, above the lowest portion of the cylindrical sidewall of the cup. They serve both for indicating when the instrument is level and for measuring the charge of material, which is approximately 250 ml.

- Jacket— The cup is surrounded by a jacket which holds water or other suitable liquid serving as a constant temperature In the type illustrated, the jacket is provided with a thermometer clamp and stirring device. A tripod supports the apparatus and also carries a ring burner by means of which the bath is heated. Adjustable legs on the tripod serve to level the instrument. Other arrangements of outer baths, supports, and stirring devices are acceptable, especially when it is desired to use inure than one standardized cup in a single bath.

- Stopper— The efflux tube in the cup is closed or opened by the insertion or withdrawal of a tapered hardwood stopper which, to leave the tube open, can be suspended by its brass pin from the hook on the cover. The stopper shall be a smooth, round wooden rod 180 mm long 8 mm in diameter, with a brass wire pin 20 mm and 1.83 mm in diameter long inserted diametrically through the rod at a point 50 mm from the lower end, and tapered uniformly below this pin to end in a circular plane 1.6 to 2.0 mm in diameter. Above the pin the rod shall be planned or grooved on four sides to a depth of 1 mm to prevent any possible restriction of air flow.

- Receivers— Two types are required as follows:

- Testing Flask— 50 ml graduate calibrated at 20 °C

- Calibration Flask— For standardization purpose there shall be available a Kohlrausch flask, with top enlarged above the graduation mark and calibrated to contain 200±0.1 mlat2O°C.

- Thermometers— ASTM Engler Thermometers 23 °C, 24 °C and 25 °C are required, and conforming to the requirements for these thermometers.

- Timer— Stop watch or other timing device graduated in divisions of 2 seconds or less and accurate to within 0.1 % when tested over a 60 minute period.

- Strainer — 300 mm ASTM sieves conforming to specification

NOTE: The distance from the bottom of the efflux tube to the top of the flask should be 130±5 mm.

PREPARATION OF SAMPLE

Stir the sample until it is homogeneous, using heat if necessary. Avoid inclusion of air bubbles, loss of volatile or other effects, which may influence the viscosity. Strain in representative portion of the sample through the strainer to eliminate particles. Strain the material directly into the viscometer if preferred.

STANDARDIZATION AND CALIBRATION OF VISCOMETER:

The efflux time for 200 mL of distilled water at 20.0°C with an acceptable Engler viscometer shall be between 50.0 and 52.0 s. Determine this time and the factor representing the efflux time for 50.0 mL of water at 25.0°C

PROCEDURE:

- Thoroughly clean and dry the cup and outlet tube of the viscometer and insert the stopper. Fill the outer bath and bring it to the required temperature of test. Maintain the bath not more than 1°C high for tests at 25°C, 40°C, or 50°C, and not more than 2 or 3°C high for tests at 100°C.

- Pour the material into the cup until it exactly reaches the tops of the three measuring points when the instrument is level. Position the 50 mL, testing flask so that the bottom of the flask is 130 (±) 5 mm below the discharge end of the efflux tube, and adjust it so that the effluent will strike the narrow portion of the neck of the flask near or slightly below the calibration line.

- Place the lid and inner thermometer into position and maintain the bath, with frequent agitation, at such a temperature that the material in the viscometer cup remains at the test temperature. Maintain these conditions for 3 min. Check the accuracy of the temperature reading by holding the stopper firmly in position and rotating the cover at short intervals during the first 2 min, but do not disturb the material during the last minute. When these conditions have been met, withdraw the stopper from the efflux tube, simultaneously start the timer, and suspend the stopper by the hook on the cover. Determine the time in seconds for 50 mL of material to flow from the viscometer.

- Determine the time in seconds for 50 ml of material to flow from the viscometer. Find time of flow for the same quantity of distilled water at the same temperature.

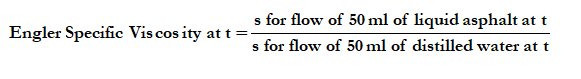

Engler Viscosity Apparatus Using the 50 mL Graduate

CALCULATIONS

Calculate the Engler specific viscosity by dividing the time of flow for 50 mL of material at the selected temperature by the factor, as previously determined, according to the following formula:

where: t = selected temperature of test, oC.

Results should not differ from the mean by more than the following amounts:

Repeatability (one operator and apparatus) 4 %

Reproducibility (different operators and apparatus) 6 %

OBSERVATIONS & RESULTS

Temperature of bitumen= 240C

Temperature of water= 210C

| GROUP | TIME REQUIRED FOR FLOW OF 50ML | ENGLER SPECIFIC VISCOSITY | |

| Liquid Asphalt | Distilled Water | ||

| (sec) | (sec) | (°ε) | |

| 1 | 47.6 | 10.38 | 4.56 |

| 2 | 52.62 | 10.64 | 4.95 |

Mean Engler Specific Viscosity = 4.76 oε

COMMENTS:

As result of group 1 is not within 4% limit of mean result, hence this result should be repeated.

While, other value is within range.