Lab 6:

Determination of Relative Density (Specific Gravity) And Water Absorption of Different Aggregate (ASTM C-127/128)

Significance:

- In this test method, we determine the relative density (i.e. specific gravity) and the water absorption of the coarse aggregates.

- The knowledge of the specific gravity is important for the concrete technologist to determine the properties of concrete made from such aggregates.

- It is used for the calculation of the volume occupied by the aggregates in various mixtures.

- The pores at the surface of the particles affect the bond between the aggregate and the cement paste and thus influence the concrete strength.

- Normally it is assumed that at the time of setting of concrete, the aggregate is in the saturated and surface dry condition. If the aggregate is to be batched in the dry condition, then it is assumed that sufficient amount of water will be absorbed from the mix to bring the aggregate in the saturated condition. If an additional amount of water is not added as a cover for the absorbed water, the loss of workability is resulted.

Apparatus:

- Weighing Balance

- Sample container

- Flask

- Sieves

- Oven

- Pycnometer

- Samples of aggregate

Related theory:

Aggregates

Aggregates may be classified as;

- Coarse Aggregates

- Fine Aggregates

Coarse aggregates:

Any material which is retained on ASTM sieve 4.75mm is known as coarse aggregate.

Fine aggregates:

Any material which is passing ASTM sieve 4.75mm is known as fine aggregate.

Types of crush available in Pakistan

SARGODHA CRUSH

Sargodha crush possess the following properties;

- Greener in color

- High strength

- Usually elongated particles

MARGALLA CRUSH

Margalla crush possess the following properties;

- Grayish in color

- Low in strength

SAKHI SARWAR CRUSH

Sakhi Sarwar crush possess the following properties;

- Whitish in color

- Moderate strength

Absorption:

“It is the increase in the mass of the aggregate due to the penetration of water into the pores of the particles during a prescribed period of time”.

The term absorption does not include the amount of water adhering to the surface of the particles. Water absorption is expressed as percentage of the dry mass.

Oven-dry (OD):

“The condition in which the aggregates have been dried by heating in an oven at 110 ± 5°C for sufficient time to reach a constant mass”.

Saturated surface dry (SSD) condition:

“It is the condition related with the aggregate particles in which the permeable pores of the aggregate particles are filled with water but without free water on the surface of the particles”.

Oven dry density:

“It is the mass of the oven dried aggregate per unit volume of the aggregate particles”.

The term volume includes the volume of the permeable and the impermeable pores and does not include the volume of the voids between the particles.

Saturated surface dry (SSD) density:

“It is the mass of the saturated surface dry aggregate per unit volume of the aggregate particles”.

The term volume includes the volume of the permeable and the impermeable pores which are filled with water and does not include the volume of the voids between the particles.

Apparent density:

“It is the mass per unit volume of the impermeable portion of the aggregate particles”.

OR

“It is the mass per unit volume of the solid portion of the particles excluding the voids”.

Specific gravity/Relative density:

“It is the ratio of the density of the aggregate material to the density of the gas free distilled water at a standard temperature (i.e. 4 oC)”.

The relative density is a dimensionless quantity and is expressed as oven dried, saturated surface dry and apparent specific gravities.

Oven dried specific gravity:

“It is the ratio of the oven dried density of the aggregate to the density of the gas free distilled water at a standard temperature (i.e. 4 oC)”.

Saturated surface dry specific gravity:

“It is the ratio of the saturated surface dry density of the aggregate to the density of the gas free distilled water at a standard temperature (i.e. 4 oC)”.

Apparent specific gravity

“It is the ratio of the apparent density of the aggregate to the density of the gas free distilled water at a standard temperature (i.e. 4 oC)”.

Procedure:

For Coarse Aggregate:

- Select by quartering or use of a sample splitter approximately 5 kg of aggregate. Reject all material passing a 4.75mm sieve.

- Thoroughly wash the sample to remove all dust or other coatings from the particles.

- Dry the sample to a constant weight at a temperature of 100 to 110°C (212 to 230°F). Cool at room temperature for about 15 min. and then immerse in water at room temperature for approximately 30 min.

- Remove sample from water and wipe the particles until all surface films are removed. Weigh the sample in this saturated surface dry condition to the nearest 0.5 g.

- Immediately after weighing, place the sample in a wire basket, suspend in water, and obtain the buoyant weight.

- Dry the sample to a constant weight at a temperature of 100 to 110°C (212° to 230°F), cool in room temperature for at least 30 min. and weigh.

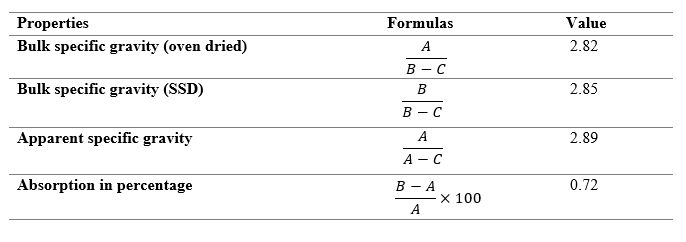

Observations and Calculations

| Oven dried weight of sample | A= | 1540 | g |

| Saturated surface dry weight of sample | B= | 1551.1 | g |

| Weight of bucket in water | D= | 2067.6 | g |

| Weight of bucket + SSD aggregate in water | E= | 3074.5 | g |

| Weight of saturated sample in water (E-D) | C= | 1006.9 | g |

For Fine Aggregate:

- Obtain by sample splitting or quartering 3000 grams of aggregate, including equal quantities of all fractions.

- Dry to a constant weight at a temperature of 100 to 110°C (212 to 230°F).

- Allow to cool and cover with water for about 30 min.

- Remove excess water and spread on a flat surface. Expose to a gentle moving flame until test sample approaches a free-flowing condition.

- Place a portion of the fine aggregate sample loosely into the mold. Tamp lightly 25 times and lift the mold vertically. If surface moisture is present, the fine aggregate will maintain its molded shape. Continue drying and testing until upon removal of the mold, the aggregate slumps slightly. This indicates that the saturated, surface-dry condition has been reached.

- Immediately introduce into the pycnometer 500.0 g of the fine aggregate. Fill the pycnometer almost to capacity and eliminate the air bubbles by agitation. Add water until the bottom of the meniscus is at the 500 cc line, etched on the pycnometer. Determine the total weight of the flask, including the sample, and the water.

- Carefully remove the fine aggregate and dry to a constant weight of 100 to 110°C (212 to 230°F) and cool for at least 30 min. and weigh.

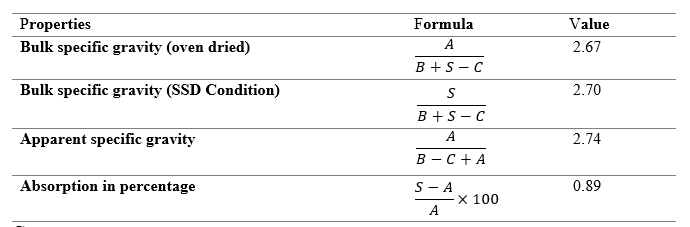

Observations and Calculations

| Empty pycnometer weight: | X= | 174.4 | g |

| Pycnometer + Sand(SSD): | Y= | 390.2 | g |

| SSD weight of Sand: (X-Y) | S= | 215.8 | g |

| Pycnometer + Water (Filled): | B= | 476.8 | g |

| Oven Dry Weight of Sample: | A= | 213.9 | g |

| Pycnometer + Sand + Water (Filled): | C= | 612.6 | g |

Comments:

- Specific gravity is used for calculating yield of concrete or the quantity of aggregate required for a given volume of concrete

- The values obtained in apparent specific gravity are maximum, hence concrete should be batched in such condition where specific gravity is maximum.