Lab 1:

Determination of percentage of water to produce normal consistency paste of hydraulic cement: (ASTM C 187-04)

Significance:

- It is used to find out the percentage of water at which the standard consistency is achieved.

- Quality of cement is indirectly measured

- This known amount of water is then used in making the cement paste for the other tests like

- Initial setting time

- Final setting time

- Soundness test

Apparatus:

- Devices for Determining Mass

- Glass Graduates, 200 or 250-mL capacity

- Flat Trowel

- Cement 650g (according to standard)

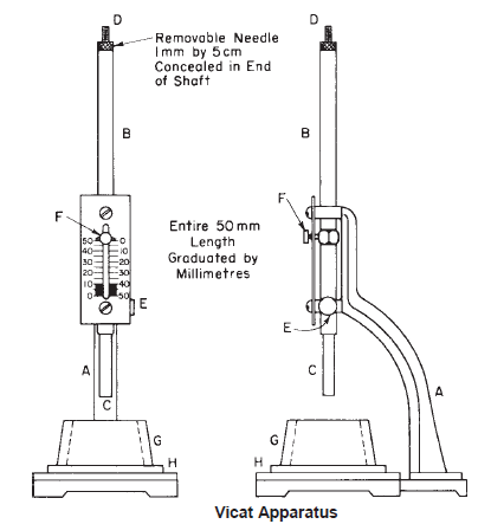

- Vicat Apparatus— including

- Frame

- Moveable rod, weighing 300g

- Plunger, being 10 mm in diameter for a distance of at least 50 mm

- Removable needle 1 mm in diameter and 50 mm in length

- The rod B is reversible, and can be held in any desired position by a set screw

- An adjustable indicator, which moves over a scale (graduated in millimeters) attached to the frame A

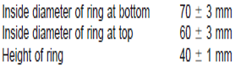

- The paste is held in a rigid conical ring

- The ring is resting on a plane non-absorptive square base plate

Related theory:

Consistency:

Measure of cohesion which is present in paste of cement is called consistency. OR

The thickness or the viscosity of the cement paste is called consistency.

Cement Paste:

The viscous mass obtained by mixing cement with water is known as cement paste.

Standard Paste:

It is the cement paste for which the 10mm diameter plunger of VICAT apparatus penetrates by 10 ± 1 mm from the surface of the paste.

Standard/Normal Consistency:

It is the thickness or the viscosity of the standard paste and is expressed as the percentage of weight of water.

Procedure:

Preparation of Cement Paste—Mix 650 g of cement with a measured quantity of water. Mixing time of cement paste should be between 4min to 4min 15s.

Molding Test Specimen—Quickly form the cement paste, into the approximate shape of a ball with gloved hands. Then toss six times through a free path of about 150 mm (6 in.) from one hand to another so as to produce a nearly spherical mass that may be easily inserted into the VICAT ring with a minimum amount of additional manipulation.

Press the ball, resting in the palm of one hand, into the larger end of the conical ring held in the other hand, completely filling the ring with paste. Remove the excess at the larger end by a single movement of the palm of the hand. Place the ring on its larger end on the base plate H, and slice off the excess paste at the smaller end at the top of the ring by a single oblique stroke of a sharp-edged trowel held at a slight angle with the top of the ring, and smooth the top, if necessary, with a few light touches of the pointed end of the trowel. During these operations of cutting and smoothing, take care not to compress the paste.

Consistency Determination—Center the paste confined in the ring, resting on the plate, under the rod, the plunger end of which shall be brought in contact with the surface of the paste, and tighten the set-screw E. Then set the movable indicator F to the upper zero mark of the scale, or take an initial reading, and release the rod immediately. This must not exceed 30s after completion of mixing.

The paste shall be of normal consistency when the rod settles to a point 10 ± 1 mm below the original surface in 30 s after being released.

Make trial pastes with varying percentages of water until the normal consistency is obtained. Make each trial with fresh cement.

Temperature and Humidity:

- The temperature of the air in the vicinity of the mixing slab, the dry cement, molds, and base plates shall be maintained between 20 and 27.5 °C (68 and 81.5 °F).

- The temperature of the mixing water shall not vary from 23.0 °C (73.5 °F) by more than 62.0 °C (3.5 °F).

- The relative humidity of the laboratory shall be not less than 50 %.

Precautions:

- Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and tissue upon prolonged exposure. The use of gloves, protective clothing, and eye protection is recommended.

- Wash contact area with copious amounts of water after contact. Wash eyes for a minimum of 15 min.

- Avoid exposure of the body to clothing saturated with the liquid phase of the unhardened material. Remove contaminated clothing immediately after exposure

- The apparatus should be free from vibrations during all the test.

Observations and Calculations

Type of cement: Ordinary Portland Cement

Manufacturer: Maple leaf

Room temperature = 20°C

| Sr. No. | Weight of Cement W1 | Weight/ Volume of water W2 | %age of water by cement (W2/W1)*100 | Depth of penetration |

| g | 1g = 1mL | % | mm | |

| 1 | 500 | 120 | 24 | 9 |

| 2 | 500 | 130 | 26 | 11 |

| 3 | 500 | 135 | 27 | 12 |

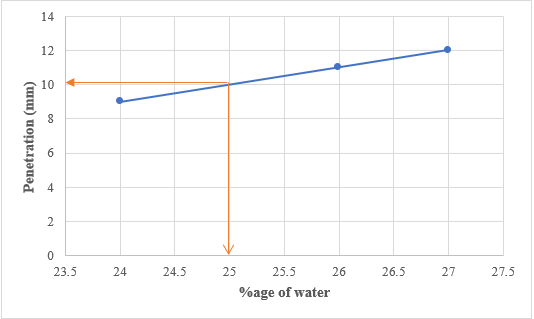

Interpolation for 10mm Penetration

Results:

From the interpolation of the data we get the standard consistency of cement against 10mm penetration of plunger as 25%

Comments:

- The test conditions i.e. temperature and relative humidity were close to the standard conditions.

- The obtained normal consistency of cement is 25% which is in the range 22 to 30%

- The normal consistency of OPC is about 30 %