Job # 2:

Determination of angularity number of the given aggregate sample

Scope & Significance:

This test is also carried out for determining shape of the aggregates. This test is performed to determine the angularity number i.e. the absence of roundness or the degree of angularity of the aggregate specimen

- The degree of packing of particles of single sized aggregate depends upon the angularity of aggregate.

- The angularity of the aggregate can be estimated from the properties of voids in a sample of aggregate compacted in a specified manner.

- The angularity number ranges from 0 for a highly rounded gravel to about 11 for freshly crushed angular aggregates.

- Higher the angularity number, more angular and less workable is the concrete mix.

- In cement concrete roads (rigid pavements) rounded aggregates are preferred because of better workability and higher strength.

- In bituminous or water bound macadam construction (like flexible pavements), angular aggregates with high angularity number are preferred because of high stability due to better interlocking and friction.

- In road construction, angularity number of 7 -10 is generally preferred.

Related theory:

Shapes of particles:

The usual shapes of the particles are;

- Rounded (river gravel)

- Angular (crushed rock)

- Flaky (laminated rock)

- Elongated

Use of different particles shapes:

- Round aggregates are preferred in concrete roads (rigid pavements) as the workability of concrete increases due to the less friction between the surfaces.

- Angular aggregates are desirable in granular base coarse (flexible pavement) due to better interlocking and increased stability.

- Angular particles possess well defined edges formed at the intersection of roughly planer faces and are commonly formed in aggregates prepared by crushing of rocks.

- Flaky and elongated aggregates are considered as a source of weakness.

Angularity:

It is the absence of roundness. An aggregate particle, which is more rounded, is less angular and vice versa.

Angularity in general is the absence of rounding of particles of an aggregate.

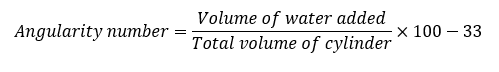

Angularity number:

Angularity number of an aggregate is the amount (to the higher whole number) by which the percentage of voids in it after compacting in a prescribed manner exceeds 33.

Where, “33” is the percentage of volume of voids in a perfectly rounded aggregate.

And, “67” is the percentage of volume of solids in a perfectly rounded aggregate when compacted in specified manner.

The value of angularity number generally lies between 0 & 11.

In road construction angularity number of 7 – 10 is generally preferred.

Apparatus:

- Metal cylinder of about 3-liter capacity

- Temping rod of circular cross section having diameter = 16mm and length = 60 cm

- Metal scoop

- Weighing balance

- Water and aggregate sample

- Graduated cylinder

Procedure:

This procedure is for aggregate size ¾” to No.4 sieve. If aggregate is coarser than ¾”, a cylinder of large capacity shall be required and amount of compactive effort or energy should be proportional to the volume of the cylinder.

- 10 Kg of the sample is taken for the test. The material should be oven dried.

- The aggregate is compacted in three layers, each layer being given 100 blows using the standard tamping rod at a rate of 2 blows/second by lifting the rod 5 cm above the surface of the aggregate and then allowing it to fall freely. The blows are uniformly distributed over the surface of the aggregate.

- After compacting the third layer, the cylinder is filled to overflowing and excess material is removed off with temping rod as a straight edge.

- The aggregate with cylinder is then weighed.

- Three separate determinations are made and mean weight of the aggregate in the cylinder is calculated.

Determination of angularity number from the solids point of view:

- Add measured quantity of water in the compacted aggregate till all the voids are filled and water appears to the surface.

- Volume of water added is approximately equal to the volume of voids in the compacted aggregate.

- Now, empty the cylinder and add measured quantity of water in it. Fill the cylinder to the surface and note that total volume of water added.

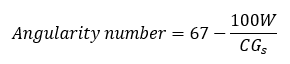

Determination of angularity number from the voids point of view:

- Find the mean weight (W) of the aggregate filling cylinder

- Find the specific gravity (Gs) of aggregates

- Find the volume of cylinder (C) by completely filling measured quantity of water in the cylinder

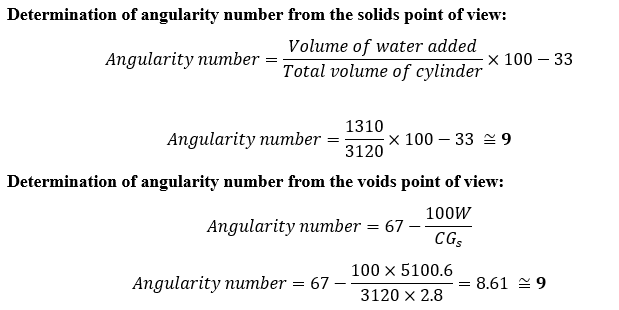

Observations and Calculations

Specific gravity of aggregate Gs = 2.80

Total volume of cylinder (C) = 3120 ml or cm3

Weight of empty cylinder = 5037.5 g

Weight of cylinder + Compacted aggregate (W1) = 10125.2 g

Weight of cylinder + Compacted aggregate (W2) =10176.8 g

Weight of cylinder + Compacted aggregate (W3) =10112.4 g

Mean weight of cylinder + Compacted aggregate = 10138.2 g

Mean weight of aggregate filling the cylinder (W) = 5100.6 g

Comments:

The angularity number calculated by both methods are same and the % difference is zero.

Moreover, the angularity number is 9 which lies between 7-10, hence these aggregates can be used for road construction